Planning to offer Custom deli paper in your business? We’ve got you covered.

At many food counters, deli paper is still plain white and easy to overlook. This misses a big chance to show off a food brand’s style and grab customers’ attention.

Today, more food businesses want custom deli paper to make their packaging pop. It’s a low-cost way to let their brand shine and look great when customers share photos online.

Also, new safety rules about inks and materials make it smart for packaging businesses to offer safe, compliant deli paper.

In this blog, we’ll explain you why custom deli paper is in demand, and what you need to know about food-safe inks and legal rules. In addition, we will also cover how you can start offering deli paper for your customers.

Table of Contents

Rising Market Demand: Why Businesses Are Choosing Custom Deli Paper

As we all know, the demand for custom printed deli paper is rising fast. To understand why, let’s look at three main drivers behind this trend, and who is buying it.

1. Branding Everywhere

Food businesses now see every piece of packaging as a chance to tell their story. A wrapper with a logo or fun pattern is like a mini billboard.

It’s especially useful in social media that when customers share photos of their food, branded wrapping shows your client’s name.

A small cost, big impact.

2. Takeout Growth

The shift to takeout and delivery is huge. Globally, the online food delivery market is expected to hit USD 173.57 billion in 2025.

In the U.S., the food delivery market alone reached about USD 353.3 billion in 2024.

Therefore, as more meals go out the door, restaurants want packaging that protects their food and promotes their brand.

The segment of packaging for online food delivery is growing too, it was about USD 4.9 billion in 2024 and is projected to more than double by 2033.

3. Moving Away from Plastic

Consumers are pushing for cleaner, greener options. Paper is often seen as more eco-friendly than plastic.

Businesses know people are watching what wraps their food. Many will pay more for paper that is sustainable, especially if it carries the brand name.

With the growing focus and benefits of sustainability, the demand for custom deli paper is steadily rising.

Who Buys Custom Deli Paper?

Here are the types of food businesses likely to buy deli paper custom:

- Restraunts

- Bakeries

- Food trucks

- Catering companies

- Butcher shops

- Coffee shops

These businesses want packaging that looks good, helps preserve food, and carries their name.

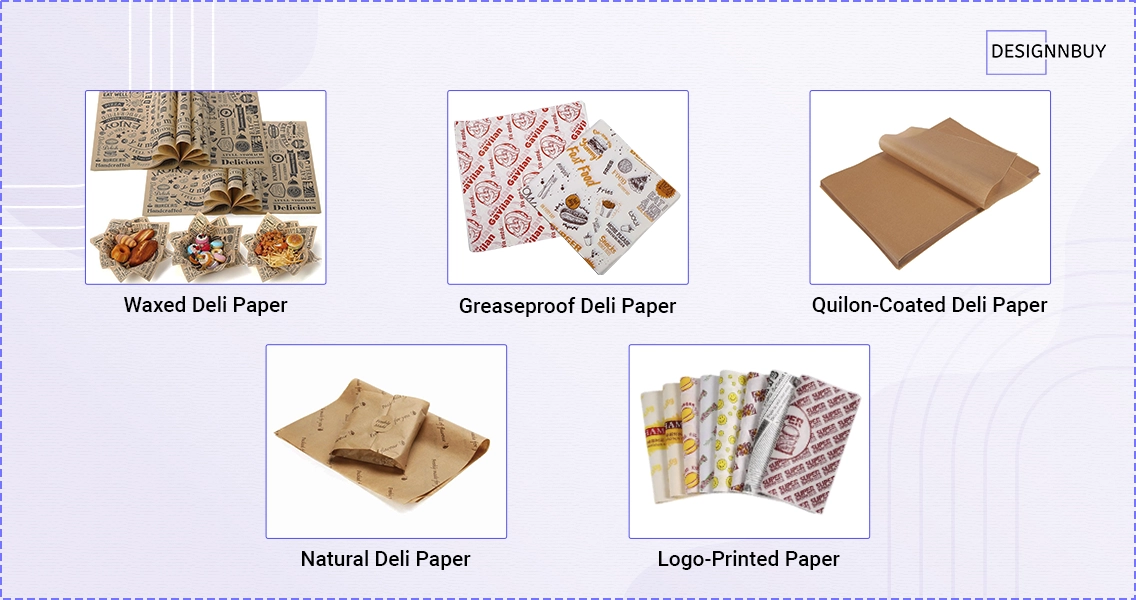

Types of Deli Paper Every Print Business Should Know

Before you start offering custom deli paper, it helps to understand the different types available. Not all deli papers are the same, and food businesses often choose based on how they use them.

1. Waxed Deli Paper

This is one of the most common options. Waxed paper has a thin coating that makes it resistant to grease and moisture.

Sandwich shops and delis love it because it keeps bread from getting soggy. It also works well for wrapping burgers, subs, or fried foods.

2. Greaseproof Deli Paper

Greaseproof paper is specially treated to stop oil from soaking through. It doesn’t have a wax layer but is still strong enough to hold oily foods like pastries, donuts, or fried snacks.

Printers often choose this type for custom printed deli paper because it provides a clean surface for bright, sharp designs.

3. Quilon-Coated Deli Paper

This paper has a chemical coating called Quilon, which gives it non-stick properties. It is often used for wrapping cheese or bakery products.

However, many businesses are moving away from Quilon because it can contain PFAS. Always check with suppliers to ensure compliance.

4. Natural / Unbleached Deli Paper

Some food businesses prefer a natural look with brown, unbleached paper. It’s seen as more eco-friendly and pairs well with rustic or organic branding.

Many coffee shops and bakeries choose this option because it matches their image.

5. Custom Pattern or Logo-Printed Paper

This is where you come in as a printer. Any of the above papers can be turned into deli paper custom with full-coverage designs, repeating logos, or seasonal prints.

Businesses use these to stand out, build brand recall, and impress customers.

By knowing these types, you can guide your clients to the best option for their food, and add more value to your printing service.

Key Trends in Custom Deli Paper 2025

The market for custom deli paper is growing, but it’s also changing. In 2025, several clear trends are shaping what food businesses expect from their packaging.

Print businesses need to understand these shifts to stay competitive.

PFAS-Free is Required

PFAS, often called “forever chemicals,” were once used to make grease-resistant paper. But health concerns have led to bans. The FDA has already pushed out PFAS, and states like California, Washington, Maine, and Minnesota now forbid its use in food packaging.

If you want to sell deli paper, your supplier must provide a PFAS-free certificate. Always keep these certificates on file to avoid legal and financial risks.

Food-Safe Inks Only

Ink safety is a non-negotiable point. More businesses now ask directly if their deli paper uses water-based, food-safe inks.

Water-based inks are not only safer for direct food contact but also better for the environment. Choosing them helps you meet regulations and win customer trust.

Fast Turnaround Expected

Delivery times matter more than ever. In 2025, many buyers expect their packaging within 5–7 days. Thanks to digital printing, this is possible.

Quick service is now a key advantage for print businesses offering deli paper.

Bold Designs Popular

The days of just printing a small logo in the corner are gone. Many brands now want full-coverage designs with color patterns, seasonal themes, or retro styles.

This not only makes the food stand out but also makes it Instagram-worthy, which boosts the food business’s visibility online.

In short, 2025 is about safety, speed, and style. Print businesses who adjust to these trends will keep ahead of competitors and win more customers.

Food-Safe Inks Explained

When printing on deli paper, ink safety is one of the most important topics you must understand.

The ink touches food directly through the paper. If the wrong type is used, chemicals can move from paper to food, creating a serious health risk.

That means liability for the business.

The Truth About FDA Approval

One of the biggest myths is that the FDA “approves” inks. This is not true. The FDA does not pre-approve printing inks.

Instead, you, as the supplier, are responsible for making sure the inks meet all rules. That requires documentation from your ink vendor and proper handling during printing.

What Makes Ink Food-Safe?

- Safe Colorants: The pigments must come from FDA-approved lists. Heavy metals like lead or mercury are not allowed. Many suppliers now use organic pigments, which are safer and more stable.

- Safe Binders: Binders hold the pigment to the paper. If the binder is not safe, chemicals can leach into the food. This is why you need full supplier documentation.

- Water-Based is Best: For custom printed deli paper, water-based inks are the standard. They have a very low risk of migration into food and meet most regulations easily.

- Proper Drying: Even the safest ink is unsafe if not dried properly. Wet ink can transfer to food. Rushing this step is a common mistake that can ruin compliance.

Documentation You Need from Ink Suppliers

You should never buy ink without full paperwork. At a minimum, you must have:

- Safety Data Sheet (SDS): full list of ingredients

- Letter of Compliance: proof the ink meets FDA rules

- Migration Test Results: lab report showing no transfer to food

- Ingredient List: detailed breakdown of all components

Migration Testing

Migration testing simulates food contact and checks if any chemicals move into the food.

These tests cost between $500 and $3,000 per ink-paper combination. It is a one-time cost per setup, and it protects you from huge liability.

Red Flags – Inks to Avoid

Never use regular commercial inks, inks without documentation, or UV-curing inks unless they are specifically certified as food-safe.

Also, avoid any ink labeled only for “indirect food contact.” That does not cover deli paper, which touches food directly.

By choosing the right inks and keeping full documentation, you keep your clients safe, meet regulations, and protect your own business from costly mistakes.

Compliance Basics

Selling deli paper custom is not just about printing a nice design. It also means meeting strict safety and compliance rules.

Ignoring these can cost your business customers, money, and even legal trouble.

Federal Requirements

In the U.S., all paper and inks used for food contact must follow FDA Regulation 21 CFR Part 176. This rule makes sure the paper and ink do not release harmful chemicals into food.

Print Businesses also must follow Good Manufacturing Practices (GMPs). That means keeping a clean workspace, storing materials properly, and maintaining accurate documentation.

If you’re into Europe, do not forget to check the EU Packaging regulations to make your business future-proof.

Migration Limits

To stay compliant, overall migration from paper to food cannot exceed 60 mg/kg.

Testing is required to prove your paper and inks meet this limit. Without testing, you cannot claim compliance.

State PFAS Bans

Some states have gone even further. California, Washington, Maine, and Minnesota already ban PFAS in food packaging. More states are expected to join this list in 2025.

If you sell non-compliant paper to these states, you could face penalties. Always ask your supplier for a PFAS-free certificate and update it each year. If you switch suppliers, test again.

Documentation System

Every order should have a digital file with:

- PFAS-free certificate from the paper mill

- Ink supplier compliance letter

- Migration test results

- A print sample for reference

Keep these files backed up and stored for at least two years. If an inspector or customer asks, you can show proof right away.

Liability Protection

Even with strong compliance, accidents happen. Protect your business with product liability insurance. Also, use contracts that include compliance clauses. When in doubt, refuse risky orders that lack proper paperwork.

Compliance is not optional. It is the foundation that makes your deli paper service safe, legal, and trusted by customers.

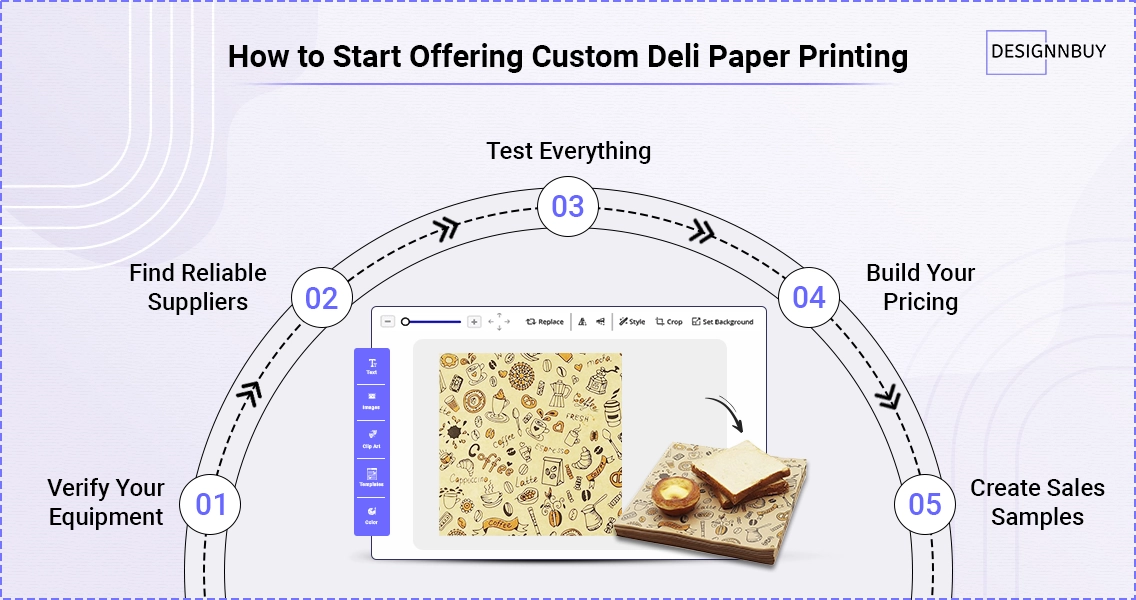

How to Start Offering Custom Deli Paper Printing

Adding custom deli paper to your print services can be a great move. But you need the right setup.

Here’s a step-by-step guide to help you get started the right way.

Step 1: Verify Your Equipment

First, check if your printer can handle greaseproof paper. Many digital printers can work well for short runs between 50 and 1,000 sheets. Also, confirm that food-safe inks are available for your model.

Step 2: Find Reliable Suppliers

You’ll need two types of suppliers, paper and ink.

- Paper supplier: Must provide a PFAS-free certification, FDA compliance letter, and consistent sheet quality. Ask for samples to test before committing.

- Ink supplier: Should provide a full compliance package, including migration test results and a letter confirming the ink is safe for food contact. Color consistency also matters for repeat orders.

Step 3: Test Everything

Do not skip testing. Print samples on actual deli paper and check if the ink dries properly.

Make sure colors match the customer’s design and confirm the paper runs smoothly through your machine.

Step 4: Build Your Pricing

Add up the cost of paper, ink, labor, and compliance documentation. Offer tiered pricing for different quantities, plus a setup fee for new designs.

Many Print business owners also charge a premium for rush orders since fast turnaround is highly valued.

Step 5: Create Sales Samples

Show potential clients what you can do. Print a few sheets with logos, full-coverage patterns, and seasonal designs. Include a spec sheet and compliance certificates with your samples.

This builds trust and makes your business look professional.

By following these steps, you’ll be ready to offer custom deli paper that meets safety standards, looks great, and delivers real value to food businesses.

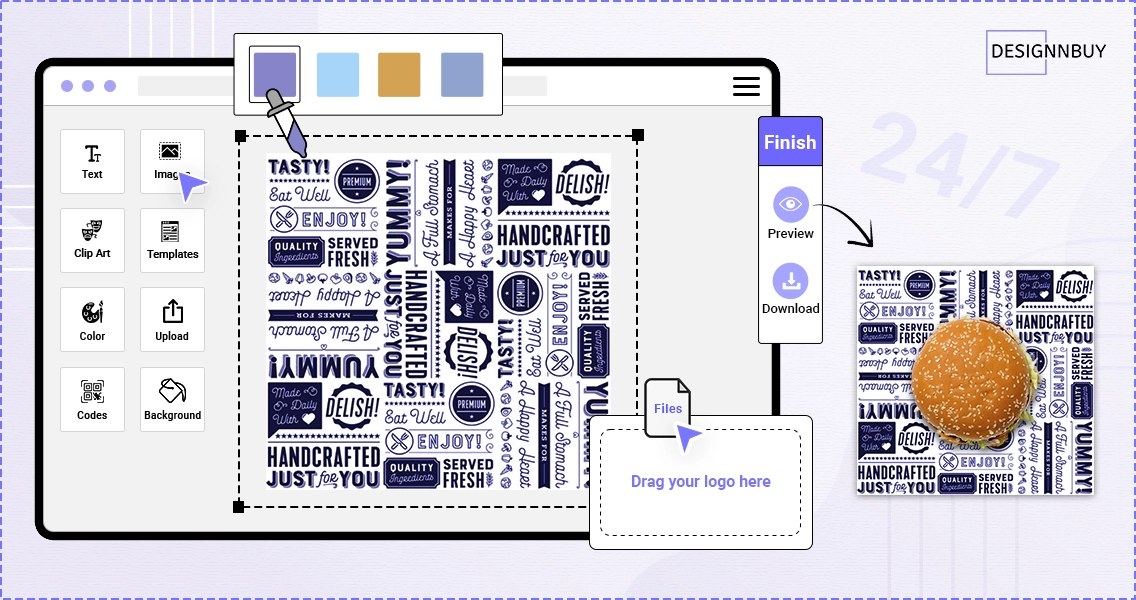

Bonus: Take it Online with a Packaging Design Software

Once your operations are ready, take your deli paper offering online with our packaging design software from DesignNBuy.

It lets your customers personalize their deli paper in real time, upload logos, preview layouts, and place orders directly on your website.

It automates order handling, reduces manual errors, and helps you sell 24/7.

With the right setup and tools, you can turn your custom deli paper service into a scalable, online-ready business that’s easy to manage and ready for growth.

5 Common Mistakes When Printing on Deli Paper

Offering printed deli paper can open big opportunities. But many printers make small mistakes that lead to big problems. Avoid these five pitfalls to protect your business.

- Using Regular Printing Inks: This is the biggest mistake. Regular inks are not safe for food contact. They can transfer harmful chemicals into food and create liability risks.

- Not Checking PFAS Status: Do not assume your paper supplier is compliant. Always ask for a PFAS-free certificate backed by lab results. Without proof, you may sell paper that is illegal in some states.

- Poor Documentation: No records = no compliance. Keep ink letters, paper certificates, and test results stored safely for at least two years. Customers may ask for them anytime.

- Rushing Drying Time: Wet ink can transfer to food. Always allow enough curing time before packaging orders.

- Ignoring State Laws: Rules differ by location. If you ship to California or Washington, your deli paper must be PFAS-free. Track customer locations carefully.

Avoiding these mistakes keeps your products safe, legal, and trusted by food businesses.

Final Takeaway: Why Custom Deli Paper Is a Big Opportunity

The market for custom deli paper is growing, and the demand shows no signs of slowing down. Food businesses want packaging that looks good, protects food, and tells their brand story. At the same time, safety and compliance rules are stricter than ever.

For printers, the message is clear. Use PFAS-free paper. Choose water-based, food-safe inks with full documentation. Keep records organized and stay up to date with new state laws. Doing these things protects your business and builds customer trust.

If you are ready to start, check your equipment, find certified suppliers, and test print samples. Then, launch your service with confidence.

Start small, but start right. Quality and compliance will set you apart and help your business grow.

Scale Your Packaging Business Online

Experience real-time design, preview, and personalization with our packaging software