Flexographic printing, or flexo, has been a key part of the packaging and labeling business for many years. It is still one of the most reliable printing methods available today because it is fast, consistent, and can print on a wide range of materials, including paper, plastic, and metallic films.

Print businesses are looking for smarter ways to keep up as the market moves toward shorter runs, faster delivery times, and more personalized designs. Combining flexographic printing with a web to print solution helps fill in that gap by adding automation, better job management, and smoother order processing to your workflow.

We’ll explain how flexographic printing works, why it’s still important for modern packaging and labeling, and how using it with a web to print solution can make your print store run more smoothly and make more money.

Let’s get started.

Table of Contents

What is Flexographic Printing?

Flexographic printing is not a new technology. People have used it everywhere for a long time, but it has changed in surprising ways. Flexography can make just about anything.

Flexo printing can be used on anything, from snack bags and chocolate wrappers to shampoo bottles and self-adhesive labels. It can also be used on cereal boxes, notebooks, pizza boxes, desk calendars, and printed paper towels.

Flexography came from rubber stamp printing, which was popular in the early 1900s. It replaced the inks used in rubber stamp printing, which were found to be unsafe for food packaging, with flexible photopolymer printing plates. These plates can put ink on almost any surface, such as metal, plastic, corrugated cardboard, paper, and even non-woven fabric.

Flexo printing is a high-speed, roll-feed web printing process that is best known for its unmatched speed. It is often used for printing labels and flexible packaging in large quantities. This printing method is incredibly fast and efficient, as shown by its ability to reach speeds of up to 2000 linear feet per minute.

Three Major Stages of Flexographic Printing Process

Flexographic printing progresses through three distinct stages: Pre-press, Printing, and Post-press. Now, let’s explore each stage meticulously.

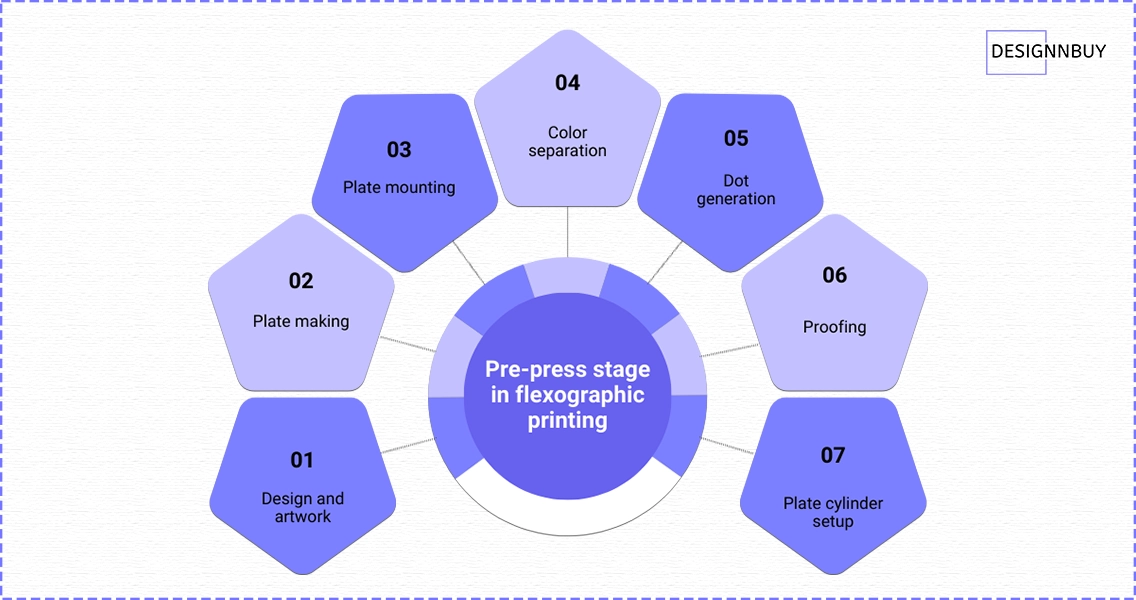

1. Pre-press stage in flexographic printing

Design and artwork

The first step of preparing for flexographic printing is to create a design or artwork that needs to be printed, using product personalization software. It should be prepared with consideration for the flexographic printing process, taking into account factors like color separation, trapping, and the use of line screens.

Plate making

The designed image is transferred to a flexographic printing plate, typically done by creating a film negative of the design. The printing plate is usually made of a flexible material, often photopolymer, which is sensitive to UV light. The plate-making process involves exposing the polymer material to UV light through the film negative. The areas exposed to light harden, while the unexposed areas remain soft.

Plate mounting

The flexographic printing plate is mounted onto a printing cylinder on the printing press. Precision is crucial during this step to ensure accurate registration of the image during printing.

Color separation

In multi-color printing, each color is separated into different plates using a set of filters to create individual color channels. Each plate represents a specific color, and the combination of these colors during printing reproduces the full-color image.

Dot generation

The process involves creating dots on the flexographic plate to represent different tones and shades. The size and arrangement of these dots determine the final appearance of the printed image.

Proofing

Before the actual printing begins, a physical or digital proof is created to verify the design and colors.

Plate cylinder setup for flexo printing presses

The flexo printing press is set up with the appropriate plate cylinders, inks, and substrate, adjusting the press to achieve proper registration, pressure, and ink transfer.

The pre-press stage is crucial for ensuring that the flexographic printing process accurately reproduces the intended design. Proper plate preparation and setup contribute to the quality and consistency of the final printed product in flexographic printing.

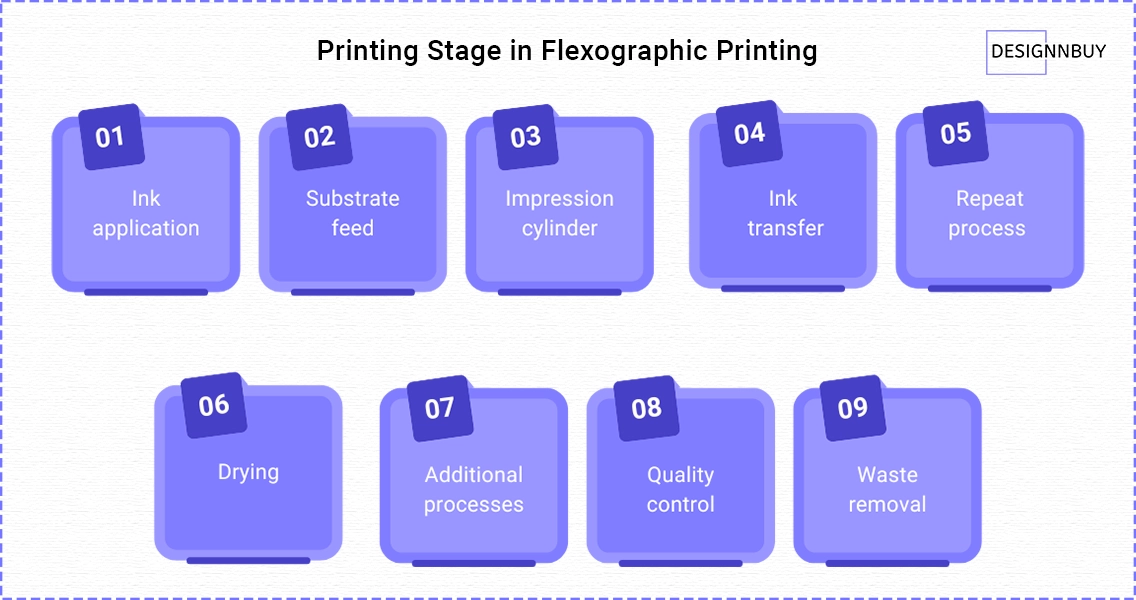

2. Printing stage in flexographic printing

Ink application

The flexographic printing presses are equipped with an inking system that applies ink to the raised portions of the flexible printing plates. The ink is typically a liquid or paste that adheres to the plate’s image areas. Specialty flexographic printing inks with unique properties or effects beyond standard printing inks such as metallic inks, fluorescent inks, and thermochromic inks are also used for the desired results.

Substrate feed

Materials such as paper, plastic, or cardboard serve as the substrate, fed through the flexographic printing press, typically in a continuous roll.

Impression cylinder

As the substrate moves through the flexographic printing press, it comes into contact with the rotating printing plate cylinder. The substrate is pressed against the inked printing plate on the plate cylinder.

Ink transfer

The inked portions of the flexible printing plate transfer the image onto the substrate. The flexible nature of the printing plate allows it to conform to the shape of the substrate, making flexography suitable for printing on various materials.

Repeat process for multiple colors

In multi-color printing, each printing unit on the press applies a different color. The substrate passes through each printing unit successively, and the colors are layered to create the final full-color image.

Drying

After the ink is transferred to the substrate, a drying process follows to set the ink with the help of air dryers, UV lamps, or other drying methods, depending on the ink type and substrate.

Additional processes

Additional processes, like coating, laminating, die-cutting, or other finishing processes, may be included based on the specific requirements of the printed material.

Quality control

Throughout the printing stage, operators monitor and adjust various parameters to ensure print quality including maintaining proper ink density, registration (alignment of different colors), and overall print consistency.

Waste removal

As the printed substrate continues its path through the press, any waste or excess material is typically trimmed or removed, resulting in the final printed product.

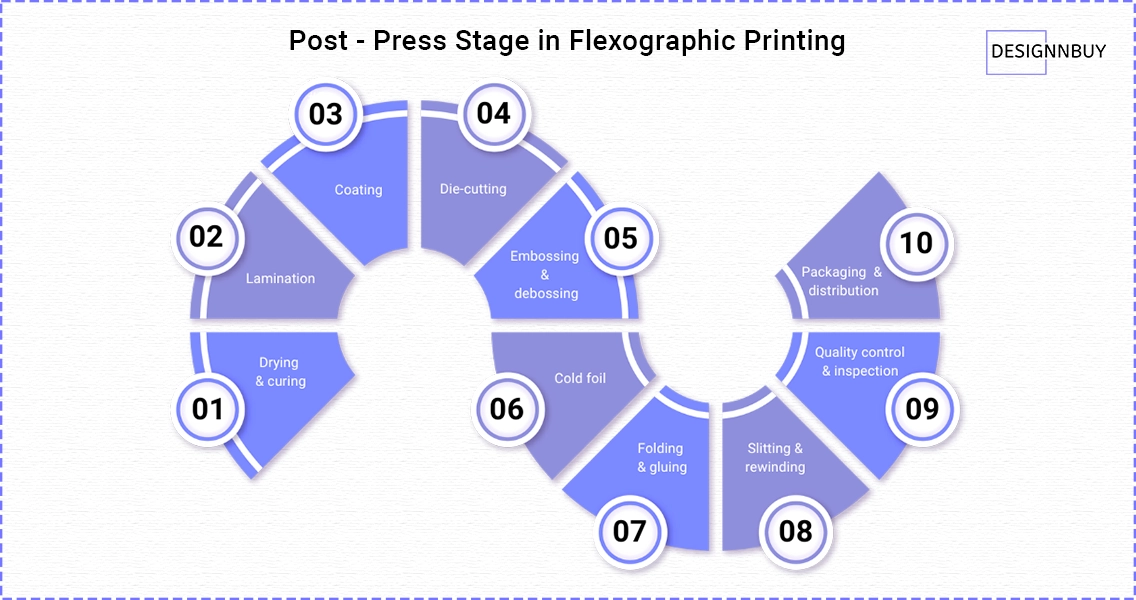

3. Post-press stage in flexographic printing

Drying and curing

After the printing stage, the printed material may undergo additional drying or curing processes, especially if UV inks are used. These processes ensure that the ink is fully set and adheres securely to the substrate.

Lamination

After drying, lamination is done for aesthetic or functional purposes by adding a thin layer of transparent film to the printed material to enhance the appearance, provide a glossy or matte finish, and protect against wear and tear.

Coating

Printed materials are coated with UV, aqueous, or other specialty coatings to achieve specific characteristics, such as water resistance, scratch resistance, or additional gloss.

Die-cutting

Next comes the cutting of printed material into specific shapes using a die which is common for labels, packaging, and other materials where a precise shape is required.

Embossing and debossing

Embossing involves creating a raised pattern or design on the printed material while debossing creates a depressed pattern. These techniques add a tactile and visual dimension to the printed product, enhancing its aesthetic appeal.

Cold foil

A process where metallic foil is applied to printed material without requiring heat, resulting in a metallic or reflective effect on specific areas. This method, often utilized for packaging, labels, and promotional materials, offers a cost-effective alternative to traditional hot foil stamping.

Folding and gluing

If the printed material is intended to be folded or assembled into a specific structure (such as a box or packaging), folding and gluing processes are applied.

Slitting and rewinding

Slitting involves cutting the printed material into narrower rolls or sheets, which is especially relevant for large rolls of printed labels or packaging. The rewinding process then prepares the material for packaging and distribution.

Quality control and inspection

Throughout the post-press stage, quality control measures are implemented to check for defects, ensure consistency, and verify that the finished product meets the specified standards.

Packaging and distribution

The final printed and finished products are then packaged and prepared for distribution, including bundling, boxing, or other packaging methods depending on the nature of the printed material.

Flexographic Printing Essentials: Equipment, Software, and Materials You Need

To run a flexographic printing business well, you need the right mix of machines, materials, and digital tools. Flexo printers can get consistent results, waste less, and turn things around faster if they have the right mix of tools, software, and materials. This keeps up with the needs of modern packaging and labeling.

1. Flexographic printing press

It goes without saying that for printing, a printing press is necessary, and flexographic printers come in various configurations to cater to different printing needs. The choice of a specific type of flexographic printer depends on factors such as the application, substrate, printing volume, and required features.

Some common types of flexographic printers are Stack Press, Central Impression Press, In-Line Press, Modular Press, Wide-Web Press, Narrow-Web Press, and Digital Flexographic Press that can handle various functions like multiple colors, printing speed, and additional features such as drying systems and inline finishing capabilities.

2. Flexographic printing plates

Responsible for transferring the image or design onto the substrate during printing, flexographic printing plates are typically made of flexible materials, and the most common is the digital photopolymer plates, made from a light-sensitive polymer material that provides high image quality and resolution.

Then there is also a rubber plate also known as an elastomer plate, made from a rubbery material, and Digital Flexographic Plates created using digital imaging technologies, bypassing the traditional film-based exposure.

3. Ink systems

Flexographic inks are extremely versatile specially formulated inks designed for use in the flexographic process on a variety of substrates. They are Water-Based Inks made primarily from water, pigments or dyes, and other additives commonly used for paper and cardboard substrates; Solvent-Based Inks, suitable for non-porous substrates like plastic films, metallic surfaces, and synthetic materials; UV Inks that are suitable for various substrates, offering high print quality.

In flexographic packaging, ink color systems are crucial for achieving accurate and vibrant colors on a variety of substrates. Flexo printers commonly use different ink color systems to achieve specific color requirements like:

Process color (CMYK) – a combination of four ink colors: Cyan, Magenta, Yellow, and Key (Black) commonly used for full-color printing to achieve a broad spectrum of colors, including photographs and detailed graphics.

Expanded gamut printing – a blend of additional inks and traditional CMYK color model, commonly used extended gamut systems include CMYK + Orange, Green, and Violet (CMYKOGV).

Spot colors – pre-mixed inks formulated to match specific colors using standardized color-matching systems like Pantone or HKS. Each spot color is a unique ink formulation.

Specialty Inks – inks such as metallic inks or fluorescent inks used for eye-catching designs in labels and packaging.

4. Anilox rollers

Anilox rollers are responsible for transferring ink from the ink pan to the printing plates and, ultimately, to the substrate. Their varying cell counts determine the amount of ink transferred, thereby affecting print quality.

5. Substrates

Flexographic printing can accommodate a variety of substrates, each with its own characteristics. Some common substrates used in flexographic printing are – paper, plastic, metalized films, cardboard and cardstock, flexible packaging materials, corrugated board, textiles, foam board, labels, synthetic papers, and so on.

6. Drying systems

The curing or drying of inks on the printed substrate in flexographic printing is carried out through drying systems like Hot Air Dryers, Infrared (IR) Dryers, UV (Ultraviolet) Dryers, LED UV Dryers, or EB (Electron Beam) Dryers.

7. Color management systems

CMS in flexographic printing ensures consistent and accurate color reproduction across various devices and print runs. These systems help maintain color integrity from the initial design stage to the final printed product. It involves the use of various components like color spaces, ICC profiles, color measurement tools, color matching software, and spectrophotometer.

8. Web To Print software

Web to print software makes flexographic printing easier by automating the processes of managing orders, approving artwork, and prepress. Customers can upload designs, change the packaging, and place orders online. Print service providers can also do jobs faster and with fewer mistakes. It connects online ordering with press production, which makes flexo print businesses more efficient, accurate, and quick.

9. CRM software

Customer Relationship Management (CRM) software helps businesses manage and analyze interactions with their current and potential customers. It streamlines processes, improves customer engagement, and enhances overall business efficiency.

10. Quality control tools

It is necessary to monitor and ensure the consistency and excellence of products or services for which certain tools are utilized that help identify and rectify defects, errors, or deviations from established quality standards. Some common, widely used quality control tools are – Flowcharts, Fishbone Diagram, Histograms, Scatter Diagrams, Statistical Sampling, Six Sigma Tools (DMAIC), etc.

11. ERP systems

Enterprise Resource Planning (ERP) systems are integrated software solutions that organizations use to manage and streamline their business processes and functions across various departments. ERP systems provide a centralized database and a unified platform for real-time collaboration, enabling efficient data sharing and decision-making.

12. Finishing equipment

Machinery and tools used in the final stages of the printing process to add special effects, refine the appearance, and prepare printed materials for distribution are finishing equipment. Some common types of finishing equipment used in flexoprinting are – Cutting and Trimming Equipment, Folding Machines, Binding Machines, Laminators, Die-Cutting Machines, Embossing and Debossing Machines, UV Coating Machines, Foiling Machines, Perforating Machines, Collating Machines, etc.

These essentials contribute to a well-equipped flexographic printing setup, ensuring efficiency, quality, and the ability to meet diverse flexographic printing companies’ requirements. The choice of equipment and materials depends on the specific needs of the printing operation and the types of products being produced.

Common Products and Applications of Flexographic Printing

Being versatile flexographic printing process finds applications in various industries. Here is a list of common products and applications of the flexographic printing process are:

- Flexible Packaging

- Labels

- Wallpaper

- Textiles

- Foil Printing

- Food and Beverage Packaging

- Folding Carton

- Envelopes

- Brown Corrugated Boxes

- Medical and Pharmaceutical Packaging

- Newspaper and Print Media

- Consumer Products

- Non-Rigid Materials

- Self-Adhesive Labels

- Home, School, and Office Products

- Marketing Materials

- Product Packaging

Flexographic printing’s ability to print on different substrates, including flexible materials, makes it suitable for a diverse range of applications.

Flexographic Printing Advantages

Flexographic printing offers several advantages, making it a popular choice for various printing applications. Here are some key advantages of flexographic printing:

- Suitable for diverse substrates, including paper, plastic, and metallic films.

- Economical for high-volume runs with low setup costs.

- Ideal for large print runs with efficient production.

- Modern technology ensures sharp images and consistent colors.

- Supports vibrant and customized color choices for branding.

- Uses eco-friendly water-based and UV-curable inks.

- Allows for laminating, die-cutting, and varnishing in the same process.

- Prints on diverse materials for packaging applications.

- Resistant to abrasion, suitable for labels and packaging.

- Well-suited for wide-format materials like banners and large packaging.

- Handles varying substrate thicknesses, providing flexibility.

- Enables efficient transitions between print jobs.

While flexographic printing has many advantages, the choice of a flexographic printing machine and method depends on specific requirements, including print quality, substrate, and production volume. Advances in technology continue to enhance the capabilities and competitiveness of flexo printing in the modern printing industry.

Flexographic Printing Disadvantages

While flexo printing offers many advantages, it also has some limitations and disadvantages. It’s important to consider these factors when choosing a printing method. Here are some of the disadvantages associated with flexographic printing:

- Involves upfront costs and lead times for plate-making, contributing to initial expenses.

- Achieving precise color matching can be more challenging in flexography compared to other printing methods.

- Flexographic inks may emit odors, and solvent evaporation during drying can be a concern, especially in sensitive environments like food packaging.

- Flexographic inks require drying time, potentially slowing down production, especially on certain substrates.

- Regular maintenance and involved cleanup processes can extend the overall production time.

- Flexographic plates can wear over time, requiring replacement for consistent print quality.

- It is less suited for variable data printing compared to digital methods.

- Flexographic presses can be noisy during operation, which may impact certain production environments.

While these disadvantages exist, it’s important to note that flexographic printing remains a widely used and cost-effective method for many applications, particularly in the packaging industry. Advances in technology and ongoing improvements in flexographic processes continue to address some of these limitations. The choice of a flexographic printing solution or method should be based on the specific requirements and priorities of the printing project.

Conclusion

Flexo printing is a winner. It deserves the top position it is today in the print market because of the set of advantages and unique features it offers. Nothing can match its versatility, speed, print quality, and automation which is what every printing professional desires.

We hope our guide has covered all the intricacies of flexographic printing, if you need to know further, stay tuned we will keep updating you on the latest and future trends about flexo printing for you.

Looking to simplify your flexographic printing? DesignNBuy helps you manage orders online through your web to print storefront.

From flexo labels to packaging and promotional items, automate proofing and streamline workflows. Reduce errors, save time, and focus on high-quality prints. Book your free demo today to see it in action.

Ready to Streamline Your Flexo Printing Workflow?

Boost speed, accuracy, and automation with a web to print solution for flexographic printing

*This Post has been Updated on Oct 2025.