Have you ever thought about how something as “simple” as packing tape could become a strategic growth engine for your printing business?

Packaging tape does not sound glamorous, but the craze of unboxing packaging videos and brands looking to make their packaging more memorable has pushed businesses to adopt custom-printed tapes.

If you are running a printing or packaging business, consider adding custom printed tape to your product offerings.

It’s not flashy. It’s not revolutionary. But here’s what it is: a high-margin, recurring-revenue product that’s becoming essential for brands across industries. And if you’re not offering it yet, you’re leaving money on the table.

For established printing businesses, adding custom-printed tape to your web to print store isn’t just diversification; it’s a strategic move that leverages your existing capabilities while opening new revenue streams.

Let’s explore what custom printed tape really is, why it’s a smart addition to your business, and how you can seamlessly integrate it into your operations.

What Custom Printed Tapes Actually Are?

Custom printed tapes are adhesive packaging tapes that feature printed designs, logos, text, or patterns specific to a brand or business.

Unlike standard transparent or brown tapes, these tapes serve dual purposes: securing packages and communicating brand identity.

They’re typically made from materials like polypropylene (BOPP), PVC, or kraft paper, depending on the application and aesthetic preference. The printing process allows for full-color graphics, solid logos, repeating patterns, or even simple text like company names and taglines.

What sets them apart from regular tape is their ability to function as a branding tool without requiring additional investment in custom boxes or labels. They integrate seamlessly into existing packaging workflows while adding a professional, cohesive look to every shipment.

How Are Custom-Printed Tapes Profitable?

According to a survey, the global adhesive tapes market is projected to grow from $80.09 billion in 2023 to $143.50 billion by 2031, at a CAGR of 6.7%.

Hence, adding custom printed tape to your packaging printing catalog is not just another product; it’s a valuable addition.

Businesses today want their personality reflected in every touchpoint, and that includes the tape holding their packaging boxes together.

Custom printed tapes have quietly become one of the most accessible entry points into personalized packaging. They’re visible, affordable, and surprisingly effective at making a brand memorable throughout the entire delivery journey.

Think of it as a mobile billboard that travels with every package your clients ship. It’s brand reinforcement at the moment of delivery, when customer excitement is at its peak.

The evolution has been significant:

- 1990s-2000s: Plain tape was purely functional

- 2010s: Basic logo printing emerged for large corporations

- 2020s: Small businesses began demanding custom tape

- 2026 and beyond: Full-color, variable data, and eco-friendly options are the new standard

Today’s custom-printed tape isn’t just for Fortune 500 companies.

Thanks to digital printing advances and streamlined production, businesses of all sizes expect, and can afford, branded tape. And that’s where your opportunity lies.

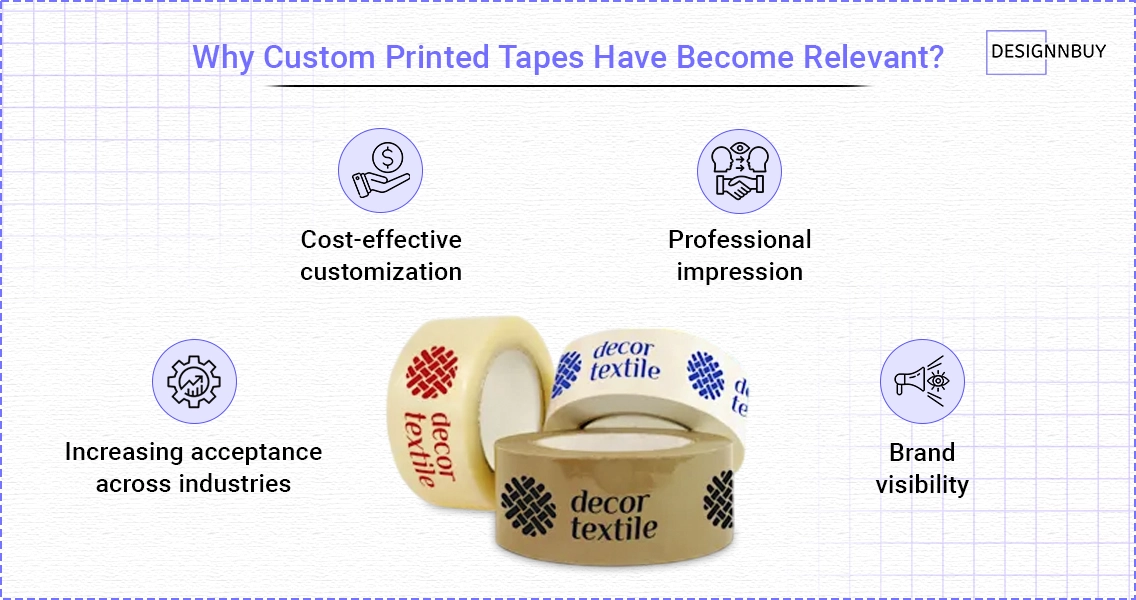

Why Custom Printed Tapes Have Become Relevant?

As we discussed above, the relevance of custom printed tape isn’t just about aesthetics. It’s rooted in how businesses communicate with their customers today.

- Brand visibility throughout shipping has become critical. When a package moves through multiple hands, from warehouse to courier to doorstep, custom tape ensures the brand remains visible at every stage. It’s a silent ambassador that works harder than most businesses realize.

- Professional impression for small and mid-scale businesses has leveled up. Companies that once couldn’t justify custom boxes now have a cost-effective alternative that still delivers a premium unboxing experience. Custom tape bridges the gap between generic packaging and fully branded solutions.

- Cost-effective customization compared to boxes or custom labels makes it an obvious choice. You don’t need to overhaul your entire packaging inventory. A roll of custom tape transforms ordinary boxes into branded assets instantly.

- Increasing acceptance across industries has normalized their use. eCommerce sellers, FMCG brands, retail chains, and logistics companies all recognize that custom tape isn’t a luxury; it’s a practical branding tool that pays for itself in customer perception.

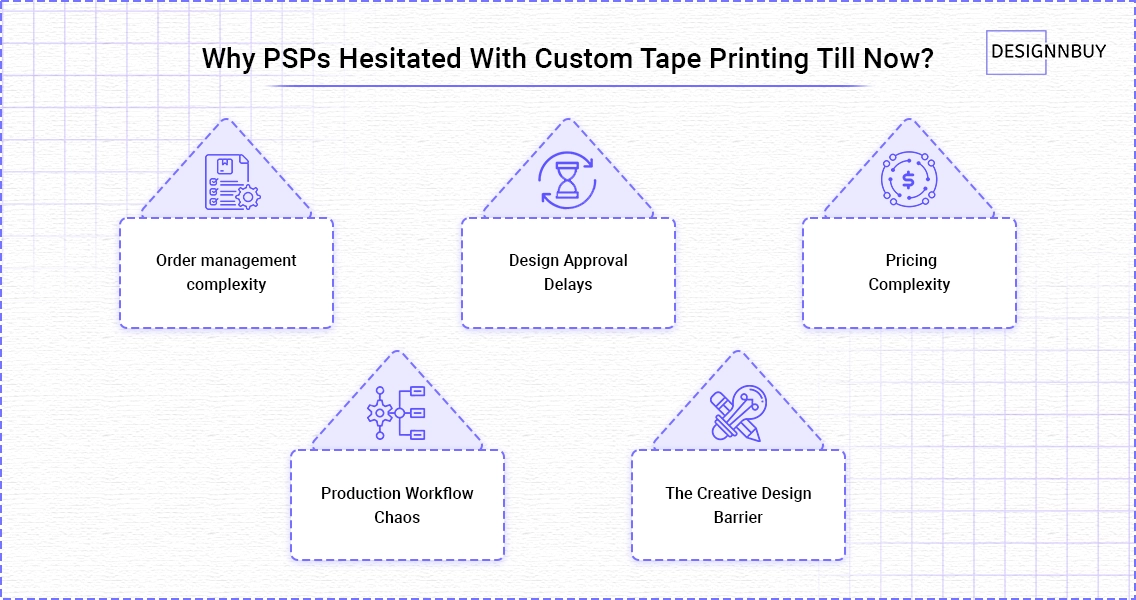

Why Print Service Providers Hesitated With Custom Tape Printing Till Now?

Let’s be honest: adding a new product line is not easy, no matter what your business type is. And, custom printed tape is no exception.

But here’s what separates thriving tape operations from those that struggle to handle the business processes efficiently.

Furthermore, most web to print shops focus on equipment and materials. That is important, but it’s only half of the equation.

The real bottlenecks emerge in order management, customer communication, and workflow coordination.

1. Order management complexity

Every custom tape order has different specifications, widths, lengths, colors, materials, quantities, and delivery timelines.

When managing these through spreadsheets, email chains, and phone calls, each order eats up 30-60 minutes of administrative time. Errors creep in as information gets manually transferred between systems.

Your sales team becomes order processors instead of relationship builders, and scalability hits a wall because growth means proportionally more administrative overhead.

DesignNBuy’s web to print software solves this by letting customers configure their own orders through intuitive online tools. The system automatically checks compatibility, calculates specifications, and routes orders directly to production, no manual data entry required.

You cut order processing time by up to 75%, eliminate specification errors, and free your team to focus on what matters: building customer relationships and growing the business.

2. Design Approval Delays

We’ve all been there: waiting days for design approvals while files bounce back and forth via email. Designers create mockups, email PDFs, wait for feedback, make revisions, and repeat the cycle.

This process makes the average approval cycles stretch to 3-7 days, and files get lost in overflowing email threads.

Having software that offers a real-time 3D preview of the designs acts as a game-changer for this challenge. Customers see exactly how their artwork looks on tape as they configure it, with a realistic rendering showing how the design wraps around rolls, how colors appear on different substrates, and how the final product will look when applied to packages.

This visual clarity reduces misunderstandings before they happen.

Along with this, automated proofreading flags errors in real time, and shareable online links allow all decision-makers to review the same design instantly. Your customers can simply share the design link to their marketing manager, warehouse supervisor, or company owner for instant feedback—no file downloads, no version confusion, just accurate designing.

Online approval workflows keep everything organized and create a complete audit trail.

3. Pricing Complexity

Custom tape pricing involves multiple variables that change constantly: base material costs that fluctuate with market conditions, printing methods, and color counts that affect setup fees, quantity break points, roll lengths and widths, and shipping dimensions and weight.

When sales reps use pricing matrices to make calculations manually, each quote takes 15-30 minutes. The result is inconsistent pricing that either eats into margins or loses deals.

Slow response time becomes a competitive disadvantage; customers often abandon their inquiry if quotes take more than 24 hours. Running promotions or testing new pricing strategies requires updating dozens of spreadsheets.

Dynamic pricing engines solve this by calculating accurate quotes instantly based on your predefined rules. Customers see pricing in real-time as they configure products, converting browsers into buyers immediately. You control pricing variables centrally, updating material costs or margins system-wide in minutes.

4. Production Workflow Chaos

Custom tape production involves multiple sequential steps: pre-press preparation, printing, slitting to final widths, core application, packaging, and quality control.

Coordinating these efficiently becomes complex when dealing with varying order priorities, different material requirements, and equipment availability.

Traditional job tickets get printed and passed between stations, requiring production meetings to establish priorities.

Manual tracking means jobs can get lost in production, and there’s no real-time visibility into what’s happening where.

Customer service can’t answer “where’s my order?” without physically walking the production floor, and optimizing equipment utilization feels more like guesswork than data-driven decision-making.

Workflow management systems transform this chaos into clarity. Orders automatically queue based on priority, material type, and equipment availability.

Real-time status tracking gives everyone, from production managers to customer service, instant visibility into every job’s location and status.

Automated customer notifications at each milestone keep clients informed proactively, reducing status inquiry calls by up to 80%.

Production reports reveal bottlenecks and efficiency metrics, enabling data-driven decisions about equipment investments and staffing. The overall impact is typically a 30% increase in production efficiency while eliminating lost jobs.

5. The Creative Design Barrier

Not every customer comes to you with professional artwork ready to print. Many have great ideas for their branded tape but lack the design skills or resources to bring them to life.

Small businesses and startups often can’t afford professional designers for every packaging element, yet they still want eye-catching, on-brand custom tape.

Earlier, getting such a job done meant either hiring expensive designers, using generic clip art that doesn’t capture their vision, or settling for text-only designs that fail to make an impact. This creates a bottleneck where interested customers abandon their orders simply because creating the artwork feels too complicated or costly.

AI-powered design tools eliminate this barrier. Customers can describe what they want—”a minimalist tech company logo with circuit board patterns in blue and silver” or “playful coffee-themed illustrations with beans and cups, and the AI generates professional-quality design options instantly. They can iterate quickly, trying different styles, color schemes, and concepts without any design experience.

The AI understands design principles like balance, contrast, and appropriate resolution for printing, ensuring generated artwork meets production requirements automatically. This democratizes custom tape ordering, making it accessible to businesses of all sizes.

How DesignNBuy’s Web-to-Print Software Elevates the Custom Printed Tape Business?

Now that we’ve looked at the operational hurdles PSPs typically face with custom-printed tape, it becomes clear that overcoming these frictions requires more than equipment upgrades or hiring additional staff.

What printing businesses need is a system that brings accuracy, automation, and customer autonomy into the process, all while keeping production teams aligned and sales teams free to focus on growth.

This is exactly where DesignNBuy’s web-to-print ecosystem becomes a strategic advantage.

1. A Customer Experience Built for Modern Buyers

DesignNBuy’s packaging design software gives your buyers the freedom to personalize their tape effortlessly.

Instead of relying on emailed mockups or unclear instructions, customers configure their tape directly online, visualize their artwork in real time, and finalize their order with confidence.

The entire experience feels intuitive and self-guided, exactly what today’s B2B buyers expect from a forward-thinking printing partner.

2. Accurate Orders From Day One

Every configuration made by the customer flows into your system with complete accuracy. No manual data entry, no misinterpreted specifications, and no time spent untangling order details later.

The software automatically validates widths, materials, colors, and roll specifications, ensuring every order is production-ready before it reaches your team.

This single shift eliminates a huge portion of admin overhead and dramatically reduces order-related errors

3. A Design Workflow That Reduces Approval Cycles

With DesignNBuy, the approval process isn’t dragged out over email threads. The platform generates high-fidelity previews of the tape, allowing customers to see exactly how the design wraps, prints, and appears on real substrates.

Review links can be shared internally within the customer’s team, and every revision, comment, and approval is tracked digitally.

This clarity accelerates decision-making and creates a smoother, traceable workflow for both sides.

4. Intelligent Pricing That Protects Margins and Builds Trust

Custom tape pricing can be complex, but DesignNBuy ensures it feels effortless. Its dynamic pricing engine reflects your actual costs, quantity tiers, and materials in real time, so customers understand the value instantly and you maintain consistent margins.

You set the pricing rules once, and the system takes care of the calculations automatically

5. Production Workflow Visibility for Every Team Member

What truly sets DesignNBuy apart from PSPs offering custom tape is operational transparency. Once an order enters the system, production teams can track every job in real time, customer service knows exactly where each order stands, and automated notifications keep buyers updated at every stage

This structure eliminates production bottlenecks, speeds up turnaround times, and reduces dependence on physical job tickets or manual checkpoints.

6. Creative Support That Opens Your Business to More Customers

DesignO’s built-in design assistance, including AI-supported artwork generation, empowers even non-designers to create high-quality tape designs.

This means more customers can complete orders independently, fewer jobs are abandoned due to a lack of artwork, and your team spends less time recreating or correcting customer files

7. A Scalable Foundation for High-Growth Print Service Providers

As demand for custom printed tape continues to grow, so does the need for a system that can support high order volumes without adding administrative strain.

DesignNBuy provides that foundation. It aligns ordering, design, pricing, approvals, and production into one connected workflow, making scaling your tape offering not only possible but profitable

Bottom Line

Custom printed tapes may look like a small addition to your packaging catalog, but in 2026, they carry much greater significance. They’re affordable, accessible, high-impact branding tools for businesses of all sizes. And for printers, they are a perfect combination of repeat revenue, manageable production, and high customer demand.

As the need for personalization becomes more deeply woven into the buying experience, custom tape naturally grows as a category. And while the tape itself remains straightforward, the experience of designing, previewing, and ordering it is what shapes customer satisfaction.

For printers and packaging suppliers, offering custom tape isn’t just about selling another product; it’s about evolving with the expectations of modern brands.

With DesignNBuy’s right digital personalization system supporting your operations, adding and scaling this category becomes simpler, faster, and far more profitable.

Grow Your Profit Margin with Custom Printed Tapes

Enable customers to personalize tape online and reduce manual tasks with DesignO.

FAQs

What is custom tape?

Custom tape is packaging tape printed with logos, brand colors, messages, or patterns. It enhances branding, improves unboxing experiences, and helps secure shipments. It’s widely used by e-commerce sellers, manufacturers, and retailers to make packages visually identifiable and more professional.

What is the difference between packing tape and packaging tape?

Packing tape generally refers to standard clear or brown tape used for sealing boxes. Packaging tape is a broader category that includes printed, branded, specialty, and material-specific tapes. All packing tape is packaging tape, but not all packaging tape is packing tape.

What are the three types of tape?

The most common packaging tape types are BOPP tape, paper/kraft tape, and PVC tape. Each type varies in strength, print compatibility, and sustainability, allowing businesses to choose the right material based on branding needs, shipping conditions, and product protection levels.

How to make printed tape?

Printed tape is created by applying artwork onto BOPP, paper, or PVC materials using flexo or digital printing. DesignO simplifies this by letting customers personalize designs online, automatically validating artwork, and routing orders into production, reducing errors and accelerating turnaround times.

How to make custom packaging tape?

Custom packaging tape is made by choosing the material, preparing artwork, and printing it through flexo or digital methods. With DesignO, customers design their tape online while printers automate specs, proofs, and orders, eliminating manual work and speeding up production from day one.

How to print custom packaging tape with my logo?

You upload your logo, adjust colors, and generate a print-ready layout. DesignO makes this effortless with real-time previews, instant pricing, and automated proofing—allowing customers to create accurate designs online while printers receive print-ready files without repetitive revisions.

Is custom tape eco-friendly?

Custom tape can be eco-friendly depending on the material. Paper and water-activated tapes are biodegradable and recyclable, making them sustainable options. Many brands prefer these to reduce plastic use, strengthen eco-branding, and meet growing environmental expectations in packaging.