The fashion industry is evolving at a quick pace. Today’s consumers are more willing than ever to follow new trends. With increased disposable incomes, changing wardrobes every six months or a year does not pose a problem. Well, what can we say? Clothing says a lot about a person.

They can decide the mood or vibe of the room and can help people define their agenda or personality. Without a doubt, clothing is an established part of a person’s life and more so because it can be customized to a great extent today.

Having said that, rapidly changing fashion trends and demand for a longer print life have led to the rise of digital textile printing. Though it has been around for over a decade now, it is recently gaining popularity as the ‘next-generation printing’ owing to the rising demand for Fast Fashion.

The durability and quality offered by digital printing have helped it gain preference over traditional textile printing.

But what is DTP?

Short for Digital Textile Printing, this technology involves printing designs directly from the computer on pre-made garments or fabric rolls. It has existed in the printing industry since 1994 but was only in use for low quantity orders by small businesses or while conceptualization at industrial levels — until now.

Industrial players have been compelled to focus on it by the constant increase in demand for personalized products. DTP offers them the efficiency and flexibility needed for mass customization at scale and affordability.

In this type of printing, designs are prepared virtually using the best textile design software. DTP reduces time to market by improving print speed and efficiency. The dye sublimation printers used for DTP come with the flexibility of printing complex designs on a wide variety of fabrics.

You can use it on silks, cotton, linens, wool, canvas, and other textured materials. DTP Calibration tools also allow profiling of textile substrates to ensure accurate colors on different fabrics to maintain printing consistency. From a technology perspective, it is more advanced.

Numbers speak volumes for DTP

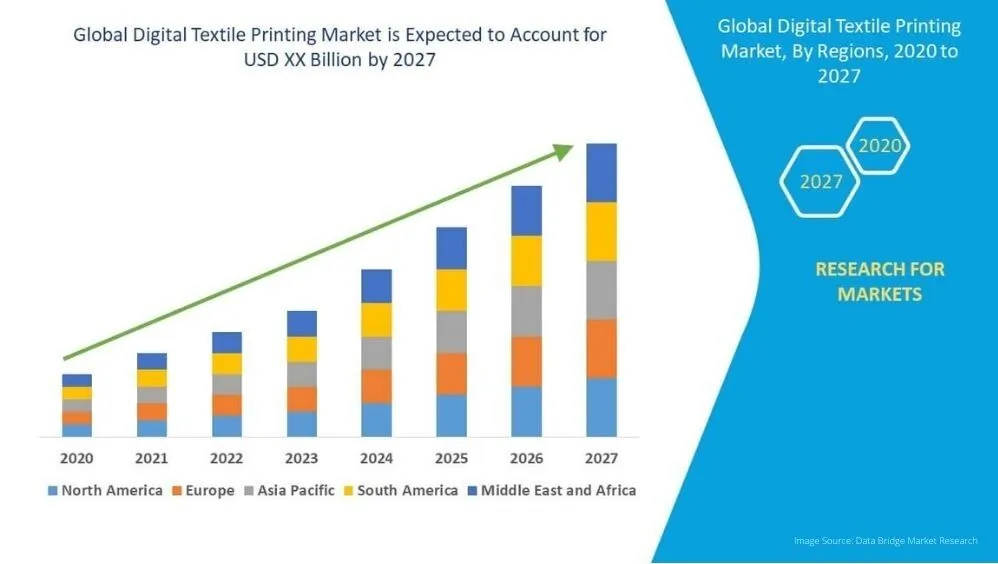

Digital printing is disrupting the global textile printing industry. Electronic procession and transmission of designs speed up the production process. Industry leaders predict a CAGR of 8.9% by 2025, reaching around $266.38 billion.

A spike in demand for apparel backed by the growth of eCommerce platforms is expected to drive the market. The fashion industry anticipates a CAGR rate of over 10% solely in the garment decoration sector, as customer preference for unique apparel is on the rise.

A region-wise review of the Global Digital Textile Printing Market by Data Bridge Market Research shows the digital textile printing market is booming across the world.

It is dominated by Europe, while Asia-Pacific is expected to exhibit a CAGR of 20.7% in the forecast period of 2020 to 2027. Rapid penetration of the apparel industry has been observed in countries such as India and China.

As mentioned previously, this is driven by progressing urbanization and swelling disposable income of millennials in these countries. Moreover, there is increased adoption of biodegradable and easily printed materials that hold the inks onto the fabric.

How DTP is better

DTP through digital inkjet printers is better compared to traditional analog printing. Some salient features are:

1. Quality prints

The colors of digitally printed fabrics bond closely with the fibers and do not fade upon washing. This results in a better quality of clothes which was otherwise a challenge with other printing techniques. Printing businesses can thus increase their sales.

2. Faster turnaround

Online printers can improve their supply chain and reduce warehouse costs because this printing process is fast and involves minimal human intervention.

Plus, eliminating the need to create design plates helps in lowering costs and saves time. The designs are made virtually on a computer using fully equipped textile pattern design software. Faster turnaround means more sales for printers. Revenues increase automatically.

3. Numerous color combinations

DTP enables printing high-quality graphics with precise colors on a variety of fabrics for multiple uses. Colors and design elements can be easily changed to create unique products. Irrespective of how intricate the design is or how many colors are involved, it is possible to execute the design and ensure the highest product quality.

4. Possibility of print-on-demand

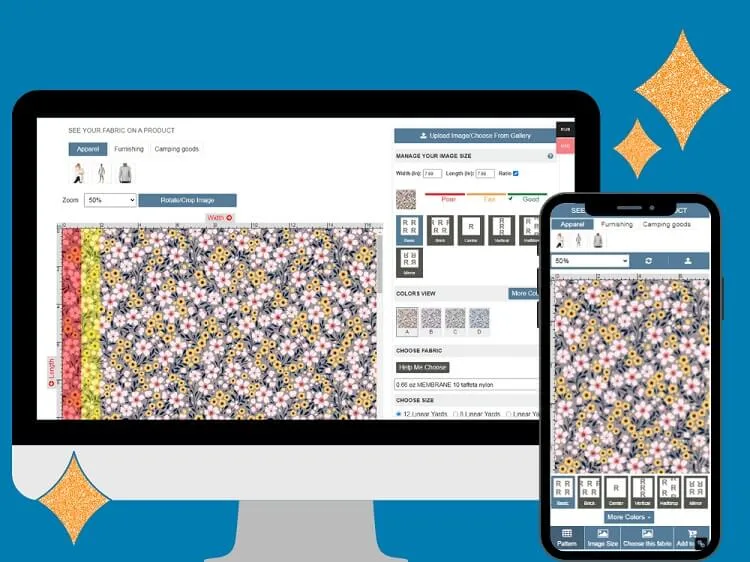

People want their apparel to be designed, printed, and delivered in the shortest possible time. Thankfully, with DTP, printers can introduce a print-on-demand business model for their customers by deploying a fabric design web-to-print software.

That way, printing businesses have the flexibility to take up low-quantity orders profitably and do not have to create dead inventory. Customers can go to the storefront, customize the desired products and place a small order. Printers can literally print that order on demand through a fabric design software solution.

5. More eco-friendly

In traditional printing processes, rotary screens would be washed before applying new screens. Since DTP happens virtually on a computer, it uses less power and water. It also uses significantly less ink and minimizes unnecessary waste.

Applications of DTP

Textile printing can be distributed into three broad categories, and each of them has different prerequisites. The next section is all about that:

1. Apparel

Digital printing has been used only for prototyping in the garment industry. However, a traditional approach is adopted while finishing the products. DTP allows printing businesses to meet the growing demand for customized products.

Web-to-print-powered textile design software solution equips digital printers with scalable and industry-level production capacity. High-quality printing is delivered in a shorter time, increasing efficiency with strong technological support.

2. Signages

The looming environmental crisis has made it imperative for end-users to reduce the usage of plastic-based soft signages. Digital printing is useful in creating large-scale visual communication such as banners, flags, backdrops, and POP/POS displays on fabrics. Digitally printed signages are consistent and durable. They are also extremely cost-effective in the long-run.

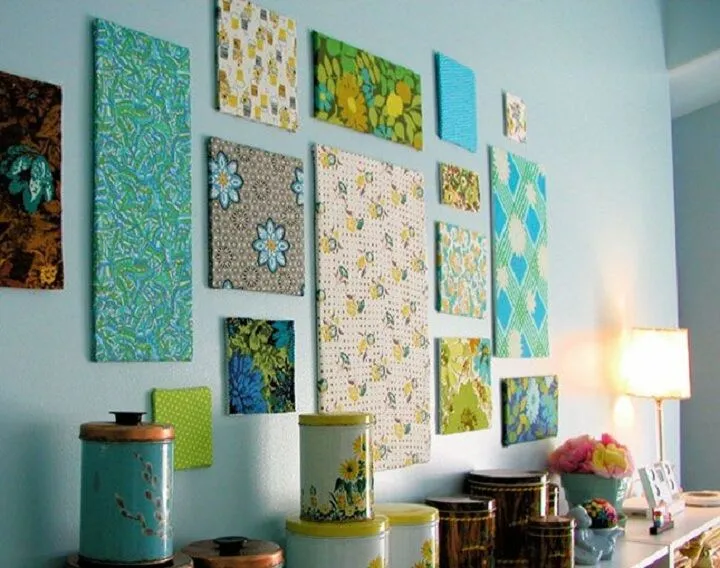

3. Décor

The most progressive market for digital printing has been home and office décor items. Products such as spring background wallpapers, posters, curtains, drapes, bed sheet sets, and cushion covers have been digitally printed for over five years. Printing businesses looking to expand their product portfolio can get on this bandwagon and benefit immensely.

The future of Digital Textile Printing is brighter than ever!

There are immense opportunities in the DTP sector. Industry forecasts exhibit an exponential rise in demand. An increase in the spending capacity of younger generations in emerging economies, cost-effective production capabilities, and the focus on sustainable printing are significant factors that will foster the growth of DTP in the years to come.

As printers discover the benefits of digital textile printing, the technology used to deliver this service is even more powerful. Web-to-print technology can empower such businesses to see opportunities ahead — from sportswear and custom printed t-shirts to fast fashion and streamline both front-end and back-end printing processes.

Moreover, with the availability of customization options, multiple payment gateways, real-time quotations, and transparent shipment tracking, customers would be more than happy to purchase their favorite custom clothing from a web-to-print storefront.

If you are looking to equip yourself with this technology, look no further. We are the leading web-to-print service providers globally and can help you sort out a digital textile design software solution that fulfills your business requirements and caters to your customers seamlessly. Request for a demo here.