We drive through a highway almost every second or third day, and without even realizing it, we’ve passed hundreds of divided highway signs in our lifetime. Those yellow diamond-shaped markers, divided highway begins, divided highway ends, divided highway ahead, blend into the background until you actually start paying attention.

In my years of working closely with print businesses, I’ve noticed something surprising: very few printing businesses tap into the traffic signage segment, even though it’s one of the most profitable and underserved niches in commercial printing. And that’s exactly why I’m writing this.

I’m not a traffic engineer. I’m someone who has spent over a decade helping print companies scale operations, optimize workflow, and discover revenue streams they never thought to explore.

And if there’s one thing I’ve learned, it’s this:

Understanding what your clients need is just as critical as having the right technology to produce it.

So let’s break down divided highway signs—what they are, why they matter, and most importantly, why this category represents a real growth opportunity for your print business in 2026 and beyond.

What Is a Divided Highway Sign?

Before we dive into the business opportunity, lets start with the basics addressing the fundamental question:

What does a divided highway sign mean?

A divided highway sign is a regulatory traffic warning that alerts drivers to changes in road configuration. The most common types you’ll encounter are:

- Divided Highway Begins Sign: Warns drivers that the road ahead will split into separated lanes (typically with a median or barrier)

- Divided Highway Ends Sign: Alerts drivers that the separated lanes are merging back into a single roadway

- Divided Highway Ahead Sign: Provides advance warning that a divided section is approaching

The divided highway sign meaning is straightforward: these signs prepare drivers for significant changes in road signs patterns that require heightened awareness and often speed adjustments.

From a print business standpoint; what divided highway sign printing can mean for your business?

Frankly speaking, sign design printing is just another product line in your wide format printing business. This addition also adds another source of recurring revenue engine to your printshop.

With a huge clientele base, and a dedicated sign design software into your production workflow, the game changes completely.

Streamlined artwork creation, ensured regulation accuracy, reduced production errors, and many other leverages, directly expands your capacity to take high-volume projects in this niche.

Why are Divided Highway Signs Worth Your Attention?

It is a growing demand

Here’s what I’ve observed across the markets we serve with our web-to-print storefront solutions:

Infrastructure spending is accelerating globally. Governments are expanding road networks, upgrading aging highways, and investing in safety improvements.

Every new road project requires standardized signage. Every road upgrade triggers road sign replacement cycles.

But here’s the part most print shops miss is that road signs have a finite lifespan. Weather exposure, UV damage, physical wear, and regulatory updates create a constant replacement cycle.

A divided highway begins sign installed today might need replacement in 5-7 years, or sometimes sooner because of harsh climates.

This creates recurring revenue potential that simply doesn’t exist with most printed products.

Who are the target audience?

In my experience working with print businesses that have successfully moved into this vertical, the customer base is surprisingly diverse:

- Municipal and state transportation departments (the obvious ones)

- Private road contractors and infrastructure developers

- Industrial parks, private toll road operators, and even parking lots

- Property management companies for large commercial estates

- Traffic management and road maintenance contractors

Each of these segments has different purchasing patterns, but they all share one thing: they need compliant, durable signage that meets regulatory standards.

It offers high profit margins

Here’s where it gets interesting from a business perspective.

Unlike banners or poster printing, traffic signs, including divided highway ends signs and other regulatory signage, must meet specific durability and visibility standards. They need to:

- Withstand outdoor exposure (rain, snow, extreme temperatures, UV radiation)

- Maintain visibility in low-light and nighttime conditions

- Remain legible and properly reflective for years

- Comply with regional and national safety standards

This higher quality bar means clients expect to pay more. And when you can deliver durable, compliant signage consistently, you’re no longer competing on price alone; you’re competing on reliability, quality, and regulatory adherence.

That’s a much better position to be in.

What Actually Goes Into Manufacturing Divided Highway Signs?

Let me walk you through what’s involved in producing road-quality signage. This isn’t standard printing, and understanding the process is crucial before you decide to enter this market.

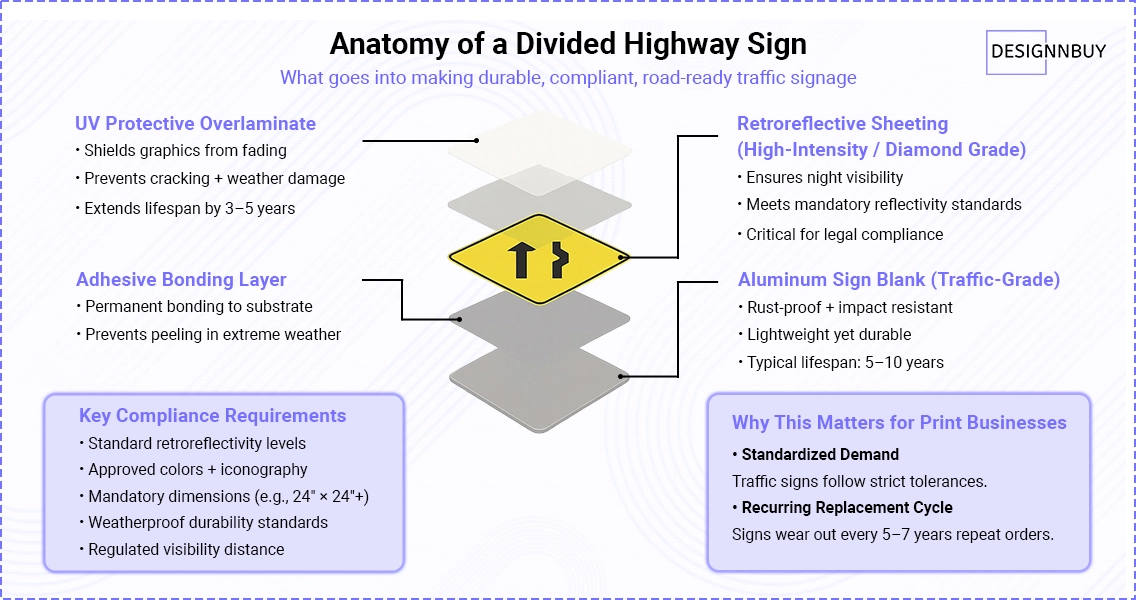

The Core Materials Matter

- The base blank: Most divided highway ahead signs and similar traffic signage and most construction signs also use aluminum as the substrate. Why aluminum? It’s lightweight, corrosion-resistant, and has excellent longevity. Some applications use steel or composite materials, but aluminum dominates for good reason.

- Reflective sheeting: This is non-negotiable for traffic signs. Retroreflective sheeting ensures visibility at night when vehicle headlights hit the sign. There are different grades (from basic to high-intensity to diamond-grade), and choosing the right grade impacts both cost and longevity.

- Protective coatings and overlays: These protect the graphics from fading, weather damage, and UV degradation. They’re what make the difference between a sign that lasts 3 years and one that lasts 10.

The Production Workflow Is More Involved Than Standard Printing

From my conversations with shops that have made this transition successfully, here’s what the typical workflow looks like:

- Cutting and shaping the metal blank: You’re working with metal sheets, not paper or vinyl. This requires different cutting equipment and precision to match regulatory dimensions.

- Surface preparation: The metal needs proper cleaning and treatment to ensure adhesion and prevent corrosion. Skip this step, and you’ll have failures down the line.

- Applying reflective sheeting: This involves laminating or pressing the retroreflective material onto the prepared blank. Proper adhesion is critical—bubbles, wrinkles, or poor bonding lead to premature failure.

- Graphics application: Depending on your setup, this might involve screen printing, digital printing on special materials, or applying pre-printed overlays. The graphics must meet regulatory specifications for a divided highway sign meaning to be clear and legally compliant.

- Finishing and quality control: Edge trimming, applying protective coatings, adding mounting hardware if specified, and thorough inspection to ensure the sign meets standards.

- Packaging and delivery: Traffic signs are often ordered in bulk, requiring proper packaging to prevent damage during shipping.

Is this more complex than banner printing? Absolutely. But that complexity is exactly what creates the barrier to entry—and the profit opportunity.

Let's Talk Numbers: Pricing, Costs, and Margin Potential

This is where my experience with print business economics really comes into play.

I’ve helped businesses analyze their cost structures and pricing strategies across dozens of product categories, and traffic signage has some unique characteristics.

Understanding Your Cost Structure

- Materials represent your biggest variable cost: Aluminum blanks, reflective sheeting, protective coatings, these aren’t cheap, and prices can fluctuate with metal markets. Bulk purchasing helps, but you need good inventory management.

- Labor and production time: The multi-step process requires skilled labor and quality control. However, once you establish efficient workflows and this is where good signage design software becomes crucial, you can achieve reasonable throughput.

- Equipment investment: You’ll need appropriate cutting tools for metal, lamination equipment for applying sheeting, and potentially specialized large format printing equipment. The upfront investment is real, but it’s amortizable across a large volume of signs.

- Overhead and waste management: Metal scraps, damaged blanks, failed applications; waste happens. Factor this into your pricing from day one.

What Clients Actually Pay And Why?

Pricing varies significantly based on several factors:

- Permanent, high-quality signs (like a properly manufactured divided highway begins sign with premium reflective sheeting and protective coatings) command premium prices. Clients understand they’re buying a product that will last 7-10 years with minimal maintenance.

- Temporary or budget signs exist in the market, but they compete primarily on price with slim margins. This isn’t where you want to be unless you’re pursuing very high volume.

- Customization adds value: Non-standard sizes, bilingual text, special mounting requirements, expedited production, these all justify price premiums.

- Volume matters: Large institutional orders (100+ signs) create economies of scale that benefit both you and the client. Your per-unit costs drop, allowing competitive pricing while maintaining healthy margins.

The Margin Reality

From the businesses I’ve worked with who’ve successfully entered this space, I’ve seen gross margins ranging from 40% to 65% on parking signage with Rydin, depending on the specific product mix and customer segment.

That’s substantially better than commodity printing, where margins are often compressed to 20-30% or less.

The key is positioning yourself as a quality and compliance-focused supplier rather than the cheapest option. When a municipal transportation department needs divided highway ends signs that will pass inspection and last for years, they’re not shopping for the lowest price—they’re shopping for reliability.

Watch the success story here:

Why Web-to-Print Solutions Matter for This Market?

Here’s where I need to put my other hat, the web to print software perspective, because this is genuinely important for anyone entering the traffic sign market.

Streamlining Complex Specifications

Divided highway signs are not creative objects. They’re highly standardized products with specific dimensions, colors, retro reflectivity requirements, and graphic standards, making them instantly recognizable.

Sign design software becomes essential for several reasons:

- Template-based production: Once you’ve built compliant templates for standard signs (divided highway ahead sign, divided highway begins sign, etc.), you can replicate them instantly for new orders

- Specification accuracy: Good sign designer software ensures every output meets regulatory requirements, no guessing, no manual measurement errors

- Faster turnaround: When a contractor orders 50 divided highway ends signs, you’re not designing from scratch, you’re pulling from your template library and producing

Client-Facing Ordering Systems

This is where web to print software really shines for this market.

Think about your typical municipal or contractor client. They’re not design-savvy, and they don’t want to be. They need to order signs quickly, know they’re getting compliant products, and track their orders efficiently.

A properly configured web2print storefront allows them to:

- Select from your catalog of standard traffic signs

- Specify quantities and any customization options

- Receive instant quotes based on your pricing rules

- Place orders without phone calls or email back-and-forth

- Track production and delivery

I’ve seen print shops reduce their order processing time by 60-70% after implementing web-to-print solutions for standardized products like traffic signage. That time savings directly impacts your capacity and profitability.

Integration with Production Workflow

The best implementations I’ve seen connect the web to print storefront directly to production systems.

When an order for divided highway begins signs comes in, it automatically generates production files, updates inventory, schedules production, and triggers purchasing if materials are low.

This isn’t just about convenience; it’s about scaling your traffic sign business without proportionally increasing administrative overhead.

The Challenges You Need to Understand (Because They're Real)

I’m not here to sell you fantasy. Every market has challenges, and traffic signage is no exception.

Let me be transparent about what you’re up against.

Material Cost Volatility

Aluminum prices fluctuate based on global commodity markets. I’ve seen businesses get caught with fixed-price contracts when metal costs spiked 20-30%.

Your pricing strategy needs to account for this, either through periodic price adjustments, metal surcharges, or contracts with pricing escalation clauses.

Compliance and Quality Expectations Are Non-Negotiable

Here’s the hard truth: if you produce a divided highway sign that doesn’t meet retroreflectivity standards, or if your divided highway ahead sign fades prematurely, you’re not just losing a client, you’re potentially facing liability issues.

Road safety signage is literally a safety product. Substandard manufacturing can contribute to accidents. While liability typically falls on the installing authority, reputational damage alone can kill your business in this market.

You must invest in quality control. Regular testing of retroreflectivity, adherence to color standards, proper application techniques, these aren’t optional.

Equipment and Setup Investment

This isn’t a market you can enter with your existing banner printer and heat press. You need:

- Metal cutting and shaping equipment

- Lamination systems suitable for reflective sheeting

- Potentially specialized printing equipment (or partnerships with suppliers who can provide printed overlays)

- Quality testing equipment (retroreflectometers, color spectrophotometers if you’re doing this seriously)

The investment can range from $15,000 to $100,000+ depending on your scale and approach. That’s not insignificant for a small to mid-size print shop.

Competition Exists (But It's Not Insurmountable)

You’re not the first person to discover this market. Established traffic sign manufacturers exist, and some have decades of relationships with state DOTs and large contractors.

Additionally, low-cost overseas suppliers compete on prices for less demanding applications.

Your competitive advantages lie in:

- Local presence and service: Fast turnaround, local delivery, responsive customer service

- Customization capability: Ability to handle non-standard requirements

- Quality and compliance: Consistent production of signs that meet or exceed standards

- Technology integration: Modern ordering systems that make clients’ lives easier

Don’t try to compete on price with overseas manufacturers or massively established suppliers. Compete on service, quality, and convenience for regional clients who value these attributes.

Inventory and Supply Chain Management

Metal blanks, reflective sheeting in multiple grades, mounting hardware, protective coatings, you’re now managing a more complex inventory than banner material and ink.

Lead times for some materials can be significant. Running out of high-intensity reflective sheeting when you have a large order due can be expensive.

This requires better inventory management systems than many print shops are accustomed to. Again, this is where modern business systems (including good web-to-print platforms with inventory tracking) become important.

Final Thoughts: Is This Market Right for Your Print Business?

So now that you have come so far, let’s come to the overwhelming question:

is this market right for your print business?

Here’s the short answer, it is for sure a real opportunity, but it is not for everybody.

If you’re a small print shop running primarily on consumer orders (business cards, invitations, small banners), the equipment investment and operational complexity might not make sense. The learning curve is real, and so are the upfront costs.

But if you are already into large format printing, the demand is high and recurring. The margins are for sure better than most standard printing. But again, a piece of advice, don’t go blindly.

Your business already possess everything machinery you need to enter this niche, but the choice of right web to print software like DesignO not only improves your operational efficiency but also create a moat around your successful business.

The web to print businesses I’ve seen succeed in this market didn’t treat it as a side hustle; they approached it as a serious business vertical that required proper investment and operational discipline.

Is it worth it? For the right print business with the right approach, absolutely yes.

Enter the highway sign printing market without any stress!

Let DesignO handle end-to-end sign creation for faster, more reliable printing.

FAQs

What is a divided highway sign used for?

A divided highway sign warns drivers when the road splits or merges. For printers, it’s a high-demand product. Many businesses now use sign-designing software to standardize layouts, ensure compliance, and produce print-ready files quickly.

Are divided highway signs profitable for print businesses?

Yes, they offer strong margins due to material durability, compliance requirements, and recurring replacements. Using web to print software helps automate artwork checks, improve turnaround time, and boost overall profitability.

How do divided highway signs fit into a print shop’s long-term product expansion strategy?

They open doors to broader traffic safety categories like directional signs, warning boards, and parking signage. Our sign design software lets printers reuse compliant templates, making it easier to scale into new signage segments quickly.

How can print shops reduce waste during divided highway sign production?

Improper design alignment, color inconsistencies, typographical errors, image and resolution errors, etc. result in rejected print files. DesignO minimizes redesign errors and ensures precise artwork alignment, reducing material rejection rates and improving overall sustainability.