Many custom printing service providers often ask: “What is the difference between offset printing and digital printing?”

Both methods are unique and excel in different areas. Offset printing is ideal for large-volume projects with consistent quality, while digital printing offers speed, flexibility, and cost-effectiveness for smaller, personalized orders.

Beyond print quality and efficiency, each method also has a different environmental impact and carbon footprint. Understanding these differences helps printing businesses make smarter operational choices, reduce waste, and meet client expectations.

With a web to print solution, custom printing service providers can seamlessly manage both digital and offset print jobs. From online order placement and proofing to automated production scheduling, the right web to print solution streamlines workflows, reduces errors, and ensures faster turnaround for every order.

Table of Contents

Why Choosing the Right Printing Method Matters

Choosing the right offset printing and digital printing method for your print and packaging business is crucial for several reasons:

1. Quality

Different printing techniques yield different qualities of output hence choosing the right method ensures that your designs, colors, and details meet the quality standards expected by your clients.

2. Cost-Effectiveness

Each printing method has its cost structure. For large volumes print job, offset printing might be cost-effective, while digital printing might be more suitable for small runs, so choosing the right one ensures you aren’t overspending on production.

3. Speed

Some methods are faster than others. Digital printing, for instance, offers quick turnaround times, which can be crucial for meeting tight deadlines, especially in industries where product launches are frequent.

4. Flexibility

Depending on your business needs, you might require the flexibility to print on various materials. Certain methods work better on specific substrates. Flexography, for instance, is excellent for packaging materials like plastics and cardboard.

5. Customization

If your clients require personalized or variable data printing then offset and digital printing methods are often the best choice. Variable data printing allows you to change elements such as text or images from one printed piece to the next without stopping or slowing down the printing process.

6. Environmentally Friendly Options

Depending on your business needs, you might require the flexibility to print on various materials. Certain methods work better on specific substrates. Flexography, for instance, is excellent for packaging materials like plastics and cardboard.

7. Innovation and Special Effects

Certain printing techniques, like screen printing or letterpress, allow for unique textures and special effects. If your business focuses on premium packaging or specialty products, these two printing methods can add significant value.

8. Brand Image

The quality of your printing reflects directly on your brand. It’s the high-quality, well-printed packaging of the product that prints your brand’s image first on the customer’s mind, leading to the perception of the product, and increased customer satisfaction and loyalty.

In short, if you want to stay ahead in the competition, win the hearts and trust of your customers, manage costs, meet deadlines, and establish your brand image, then choosing the appropriate printing method is pivotal. It’s a decision that directly impacts your business’s efficiency, reputation, and bottom line.

What is offset printing?

Offset printing, which is also known as offset lithography, is a method in which an image is first moved from an aluminum plate to a rubber blanket and then to the final paper or substrate. The ink isn’t put directly on the paper, so it’s called “offset.”

This method is great for printing a lot of copies. Once they are set up, offset presses work well and make prints that are sharp, clean, and professional-looking with colors that are true to life. It also cuts down on waste and emissions, which lowers the cost per unit.

Offset printing is still the best choice for brochures, packaging, labels, and other large projects where quality and consistency are very important.

Offset Printing Setup Process and How It Works

Offset printing may seem hard, but once you know how to set it up, you’ll see why it’s great for projects that need a lot of copies and high quality. This is how it works, step by step:

Making the Plate: The first step is to make an aluminum plate with the picture that will be printed on it. There needs to be a different plate for each color in the design.

Ink Application: The plate is covered in ink, which moves the picture to a rubber blanket. This is why the printing is called “offset.”

Printing on the Substrate: The rubber blanket rolls the image that has been inked onto the final substrate, which can be paper, cardboard, or something else. This makes sure that the ink is spread evenly and the details are clear.

Registration and Color Checks: To make sure that the prints are always high quality, printers carefully line up each color plate (registration) and keep an eye on the color accuracy.

Mass Production: After everything is set up, the press can efficiently run thousands of sheets, making sharp, clean, and professional prints at a lower cost per unit. Streamline your high-volume printing with our advanced offset printing software.

Offset printing is great for big jobs because it takes a while to set up, but it gives you consistent quality, accurate colors, and professional results that are hard to beat with other printing methods.

What is digital printing?

Digital printing is best for short print runs, which are usually less than 150 pieces. It doesn’t use plates like offset printing does. Instead, technologies like toner or liquid ink are used to digitize the image and print it directly on machines like HP Indigo, Canon, Konica Minolta, Ricoh, and Xerox.

This digital printing method is faster, more flexible, and great for making personalized or small-batch items like calendars, marathon bibs, greeting cards, flyers, and samples. One of the best things about digital printing is that it can print different data on each piece, like codes, names, or addresses. Offset printing can’t do this.

Digital printing is quick, easy, and customizable, which is why online custom printing service providers choose it for their fast, personalized products.

Digital Printing Setup Process and How It Works

Digital printing is made for fast, flexible, and small to medium print runs. It doesn’t need much setup, which makes it perfect for custom and on-demand products. This is how it works:

Design Preparation: The document or image is scanned and put together on a computer. At this point, any personalization, variable data, or customizations are added. Boost speed and personalization with our digital printing software.

File Processing: The printer gets the digital file right away. You don’t need plates, which cuts down on setup time.

Ink or Toner Application: The printer uses technologies like laser, inkjet, or liquid toner systems (HP Indigo, Canon, Ricoh, etc.) to put ink or toner directly on the substrate.

Printing and Finishing: The printer makes the right number of items, whether they are 20 flyers or 100 personalized greeting cards. As needed, finishing steps like cutting, folding, or binding are done.

Checks for Quality: Each piece can be checked for accuracy, color consistency, and personalization, so even short runs will have high-quality output.

Digital printing is quick, adaptable, and cheap for small runs, projects with changing data, and printing on demand. This makes it perfect for online custom printing service providers who want to get personalized items to customers quickly.

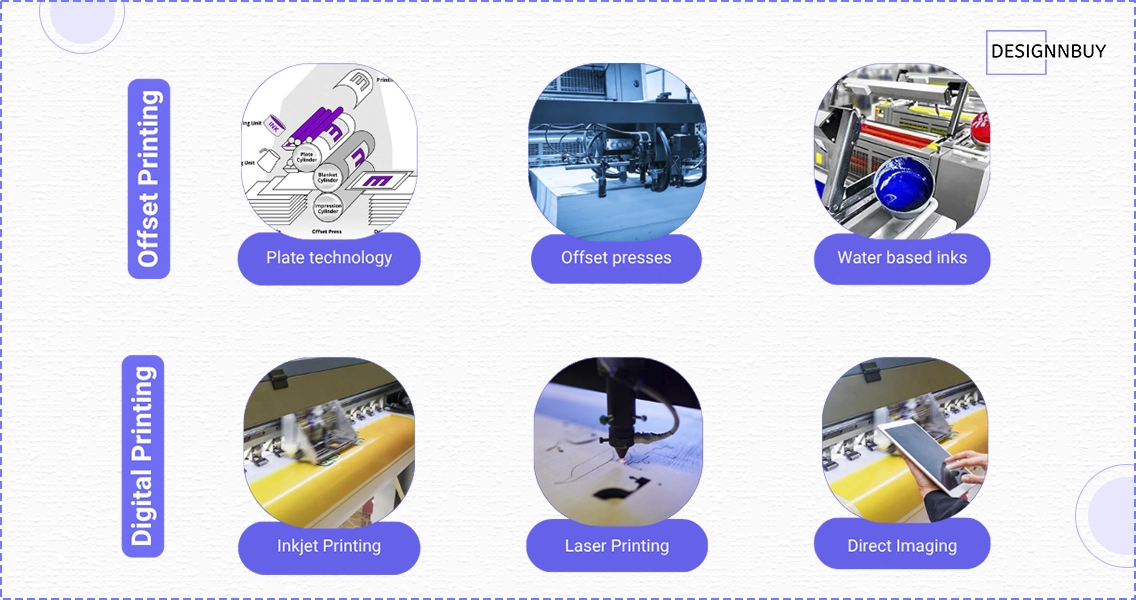

Technology Behind Offset and Digital Printing

Both digital printing and offset printing employ distinct technologies tailored to their respective processes. Here’s a breakdown advantages and disadvantages of offset printing and the key technologies used in each method:

Offset Printing

1. Plate Technology

Offset printing uses metal plates with an image etched onto them. Traditional offset printing often involves aluminum plates coated with photosensitive emulsion. These plates transfer the inked image onto a rubber blanket, which then presses it onto the paper.

2. Offset Presses

Offset presses consist of several cylinders, including plate cylinders, blanket cylinders, and impression cylinders. These cylinders work together to transfer the inked image onto the paper with high precision and consistency.

3. Water-Based Inks

Offset presses consist of several cylinders, including plate cylinders, blanket cylinders, and impression cylinders. These cylinders work together to transfer the inked image onto the paper with high precision and consistency.

Digital Printing

1. Inkjet Printing

Inkjet technology is prevalent in digital printing. It involves propelling droplets of ink onto the printing surface. Inkjet printers are versatile and can handle a wide range of substrates like paper, fabric, and plastic.

2. Laser Printing

Laser printing uses electrostatically charged toner powder, which is fused onto the paper using heat. Laser printers are commonly used for high-speed, high-quality digital printing applications.

3. Direct Imaging Presses

These presses use a digital file to directly image the printing surface without the need for printing plates enabling quick and efficient printing processes, making it ideal for short print runs and variable data printing.

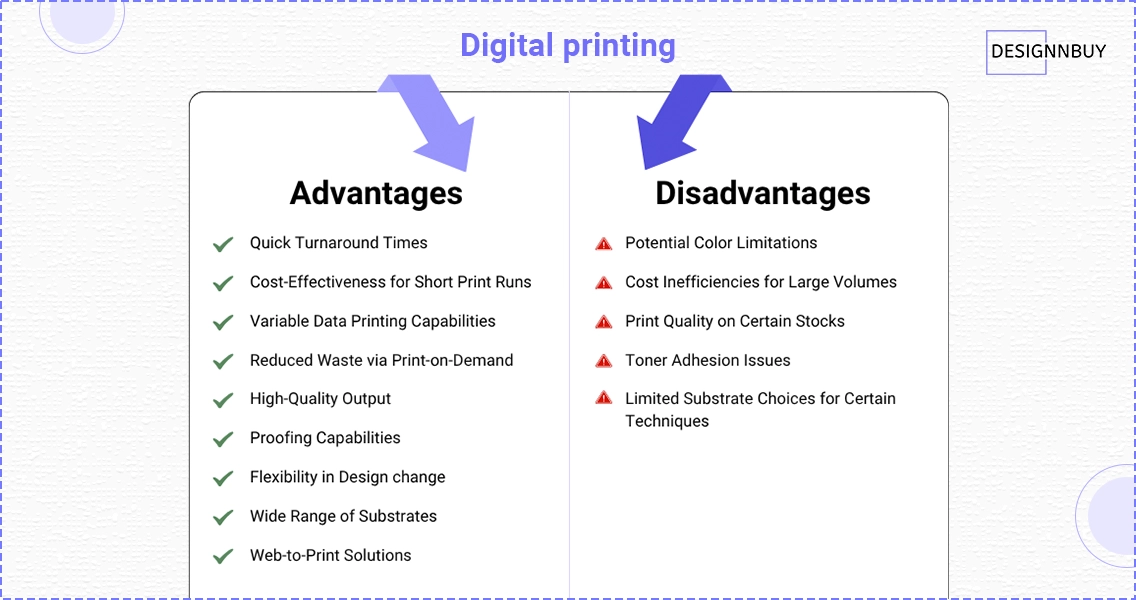

Advantages and limitations of Digital printing

Advantages Of Digital Printing

Quick Turnaround Times

Digital printing eliminates the need for lengthy setup processes such as plate creation, allowing for rapid printing, and hence is ideal for projects that require fast delivery.

Cost-Effectiveness for Short Print Runs

Digital printing is economical for short print runs because it doesn’t involve the high setup costs associated with traditional methods. Businesses can print only the quantity they need, reducing excess inventory.

Variable Data Printing Capabilities

Digital printing allows for personalized and variable data printing. Each print can be unique, making it highly suitable for customized marketing materials, direct mail campaigns, and promotional items.

Reduced Waste Through Print-on-Demand

With digital printing, businesses can print on demand, reducing the need for large print runs and minimizing waste. It is environmentally friendly and cost-effective for businesses with fluctuating or unpredictable print needs.

High-Quality Output

Modern digital printing technology produces high-quality prints with sharp text, vibrant colors, and intricate details. Advancements in digital printing have significantly improved print quality, making it suitable for various applications, including marketing collateral and photo books.

Proofing Capabilities

Digital printing allows for easy and cost-effective proofing. Businesses can review digital proof before printing the entire job, ensuring that the final prints meet their expectations in terms of layout, colors, and content.

Flexibility in Design Changes

Digital printing enables on-the-fly design changes without additional setup costs. It helps businesses that frequently update their marketing materials or need to incorporate real-time information into their prints.

Wide Range of Substrates

Digital printing can be done on various substrates, including paper, vinyl, fabric, and more allowing businesses to create a wide range of printed materials, from banners and posters to labels and promotional products.

Web to Print Solutions

Digital printing integrates well with web to print solutions, allowing businesses to automate the ordering and printing process. Customers can place orders online, and the printing process can start immediately, streamlining the entire workflow.

Disadvantages of Digital Printing

Potential Color Limitations

While digital printing technology has advanced significantly, achieving precise color matching, especially for specific Pantone colors, can be challenging compared to offset printing.

Cost Inefficiencies for Large Volumes

For very large print job runs, digital printing can be more expensive per unit compared to offset printing. Offset printing becomes more cost-effective for bulk quantities due to lower per-piece print job costs.

Print Quality on Certain Stocks

While digital printing is versatile, it may not produce the same level of sharpness and detail on certain textured or specialized papers as offset printing can.

Toner Adhesion Issues

Some digital printing techniques, particularly in toner-based systems, might face challenges with adhesion on certain substrates, leading to issues like cracking or flaking after printing.

Limited Substrate Choices for Certain Techniques

While digital printing can accommodate various materials, some specialty techniques (e.g., embossing, letterpress) are better suited for offset printing due to the specific requirements of these methods.

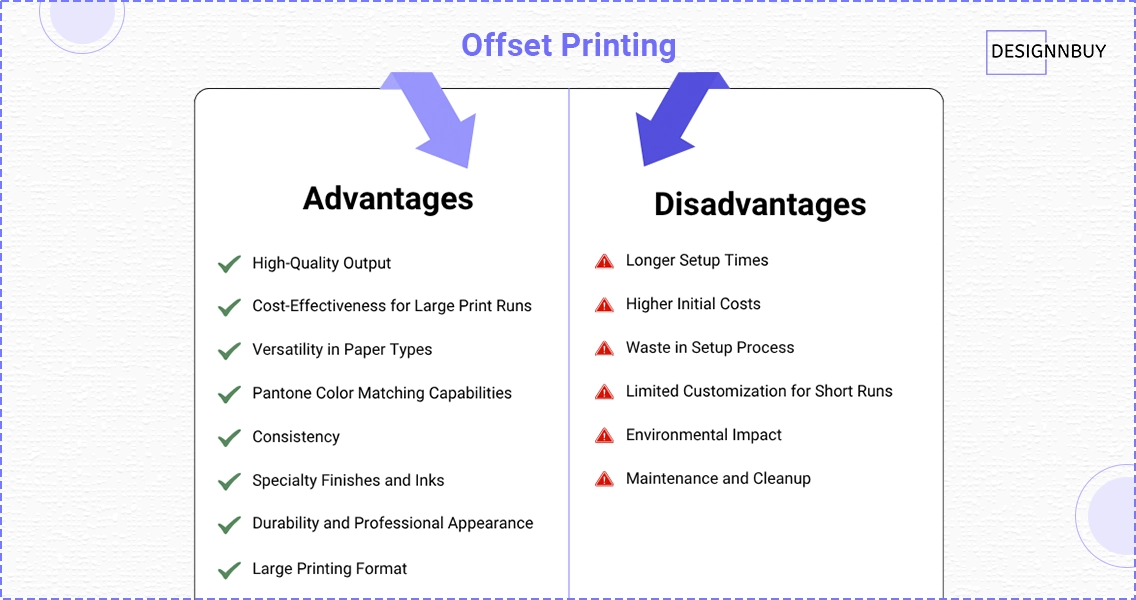

Advantages and Limitations of Offset Printing

Advantages of Offset Printing

High-Quality Output

Offset printing produces sharp, clean, and high-resolution images, making it ideal for intricate designs and detailed graphics, especially for commercial printing and large format printing requirements.

Cost-Effectiveness for Large Print Runs

Once the setup is complete, the cost per unit decreases for larger print runs, making it economical for mass production.

Versatility in Paper Types

Offset printing can be done on a variety of paper types, including textured, smooth, coated, and uncoated papers, allowing for diverse printing applications.

Pantone Color Matching Capabilities

Offset printing offers precise color matching capabilities, crucial for maintaining consistent brand colors and producing vibrant, accurate prints.

Consistency

Offset printing delivers consistent color and image quality across the entire print run which is crucial for maintaining brand identity and ensuring that every printed piece matches the desired standard.

Specialty Finishes and Inks

Offset printing supports various custom finishes, such as embossing, foil stamping, and spot varnishes, which can enhance the visual appeal of printed materials. Additionally, it accommodates a wide range of inks, including metallic and fluorescent inks.

Durability and Professional Appearance

Offset printing results in durable prints with a professional appearance. The ink penetrates the paper, creating a lasting impression that can withstand handling and environmental factors.

Large Printing Format

Disadvantages of Offset Printing

Longer Setup Times

Setting up offset printing involves creating plates and fine-tuning the press, which can be time-consuming, especially for small print jobs. Digital printing, by contrast, has much quicker setup times.

Higher Initial Costs

The initial setup costs, including plate creation and press preparation, can be significant. For small print runs, these costs may not be justifiable compared to the advantages and disadvantages of digital printing.

Waste in Setup Process

Offset printing generates waste during the setup process, including discarded sheets used for calibration and testing. Digital printing, particularly print-on-demand, reduces this type of waste significantly.

Limited Customization for Short Runs

Offset printing is generally less suitable for highly customized or personalized prints in short runs. Digital printing excels in variable data printing and short-run customization.

Environmental Impact

Traditional offset printing often uses petroleum-based inks and involves more chemical processes compared to digital printing, which might not be as environmentally friendly.

Maintenance and Cleanup

Offset presses require regular maintenance and cleanup involving various chemicals, which can be labor-intensive and potentially hazardous if not handled properly.

Remember, a careful evaluation of the pros and cons of two printing methods in the context of the particular printing project is necessary to choose between offset printing vs digital printing.

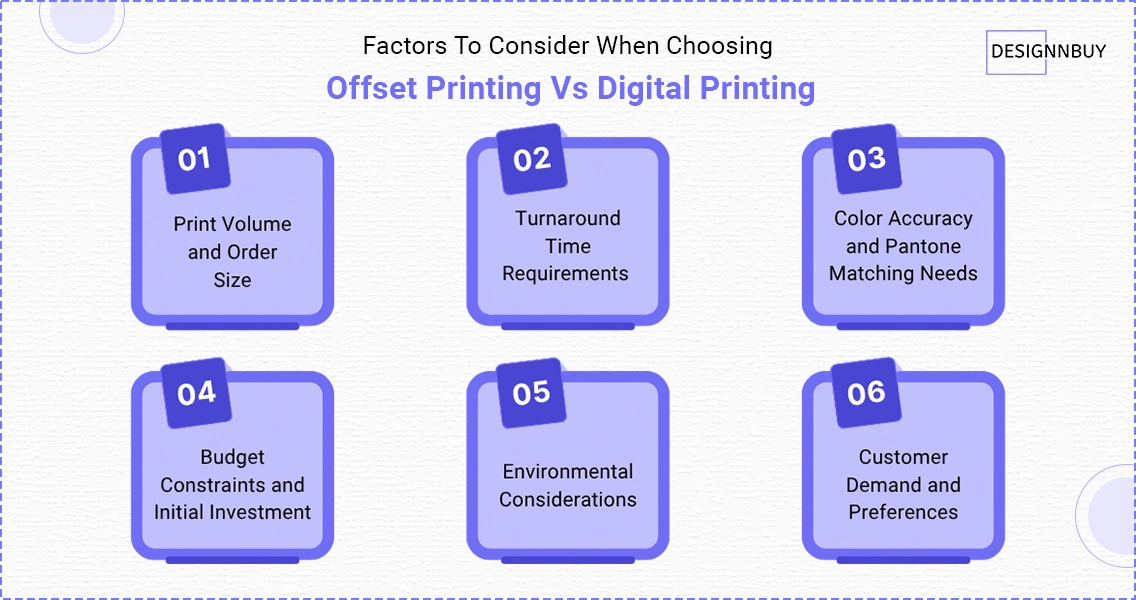

Factors To Consider For Investment: Offset Printing Vs Digital Printing

Investment is a huge step and therefore before putting all your life savings, there are certain factors to be taken into consideration and they are as follows:

Print Volume and Order Size - How Huge is Your Printing Job?

If you have received large enough print job volumes, then offset should be your choice but if it’s a small to medium-sized print job then digital printing will be the best option as it is cost-effective for small quantities due to minimal setup time and costs.

Turnaround Time Requirements - Is the Clock Ticking?

Longer setup times make offset printing less suitable for urgent orders, on the contrary, digital printing is ideal for projects with deadlines.

Color Accuracy and Pantone Matching Needs

Offset printing offers precise color matching, including Pantone colors, ensuring consistent branding. While advancements have been made in digital and offset printing technology, achieving exact Pantone matches can be challenging. Color accuracy may vary, especially in some digital systems.

Budget Constraints and Initial Investment - How Tight Are You on Your Budget?

Higher initial setup costs make offset printing expensive but economical for large print runs. Whereas, lower setup costs make digital printing suitable for businesses with limited budgets and smaller projects.

Environmental Considerations - Are You a Nature Lover?

Traditional offset printing can involve more chemicals and higher waste due to setup processes but if you have concerns about nature, you must choose digital printing because it offers reduced waste through print-on-demand, making it more environmentally friendly. Some digital printing methods use eco-friendly inks and have a lower environmental impact.

Customer Demand and Preferences - Want to Serve Your Customers What They Ask?

Offset printing is preferred for high-quality, premium products where color accuracy and detail are paramount but customization is difficult in it. Digital printing suits businesses with a focus on quick turnaround, variable data printing, and personalized marketing materials tailored to individual customer preferences.

When print service providers consider these factors, they can make informed decisions about whether to invest in offset or digital printing technologies. Often, a hybrid approach, integrating both technologies based on specific client needs, offers the most versatile and cost-effective solution for many print service providers.

Offset Printing vs Digital Printing: Cost Comparison

From invisible things like software to huge printing equipment, everything requires money and to ensure that it doesn’t go to waste, here’s a detailed cost analysis for you.

Setup Costs

- Offset printing involves significant setup costs due to the creation of printing plates. The cost varies based on plate material, size, and complexity of the design. It also requires the setting up of an offset press including calibration, ink mixing, paper loading, and skilled labor adding to the setup expenses.

- Digital printing eliminates plate creation costs, reducing initial setup expenses significantly. It does require calibration for color accuracy, but the process is quicker and involves less labor than offset calibration.

Material Expenses

- Paper costs depend on the type, quality, and quantity needed for the print run in offset printing. Offset inks, often oil-based or water-based, contribute to the material expenses.

- Digital printing uses toner or liquid ink. Cost depends on printer type, ink/toner volume, and paper type/quantity.

Labor Costs

- Offset printing requires skilled press operators who handle setup, printing, and maintenance tasks. Labor is needed for finishing processes such as cutting, binding, and quality control.

- Digital printing presses too require skilled operators, though the setup process is quicker and requires less expertise than offset printing. Labor for finishing processes, including cutting and binding, is still required.

To put it simply, offset printing incurs higher costs for setup but is a cheaper option for high-volume digital vs offset printing due to lower per-unit costs. Digital printing is cost-effective for short to medium runs due to minimal waste and print-on-demand capabilities.

Choosing Between Digital and Offset Printing

| Feature | Digital Printing | Offset Printing |

|---|---|---|

| Technology | Utilizes advanced digital inkjet or electrophotographic methods | Uses traditional mechanical printing with ink and plates |

| Setup Time | Quick setup with minimal preparation and no need for plates | Longer setup time due to plate creation and press calibration |

| Print Volume | Ideal for short to medium print runs | Economical for large print volumes |

| Customization | Excellent for variable data and personalized printing | Limited customization options for short runs |

| Color Accuracy | Good color accuracy, especially with advancements in technology | Precise color matching, including Pantone colors |

| Speed | High-speed printing suitable for rapid production | Slower setup but high-speed printing once set up |

| Quality | High-quality prints, especially for digital presses with advanced features | Excellent print quality, especially for detailed designs |

| Substrates | Versatile – can print on paper, plastic, fabric, and more | Primarily suitable for paper-based materials |

| Cost-efficiency | Cost-effective for short to medium runs due to minimal setup costs | Economical for large quantities due to lower per-unit costs |

| Special Finishes | Limited options for specialty finishes | Offers a wide range of specialty finishes like embossing, foiling, etc. |

| Waste Generation | Low waste generation due to print-on-demand capabilities | Setup processes generate waste; not ideal for minimal print runs |

| Sustainability | Can be eco-friendly with eco-solvent inks and recycled substrates | Traditional offset may use petroleum-based inks; waterless offset is more eco-friendly |

| Applications | Labels, packaging, textiles, signage, personalized marketing materials | Newspapers, magazines, books, high-end marketing materials, and other printing works |

Environmental Impacts: Digital Printing Vs Offset Printing

Both methods have environmental implications. Offset printing uses petroleum-based inks and chemicals, which can be harmful to the environment. Ink cleanup and disposal processes can contribute to pollution. It also requires a significant amount of water, primarily in the dampening process, leading to water wastage. Setup processes and calibration prints in offset printing can lead to paper wastage, especially in smaller print runs.

On the other hand, the production and disposal of toner and ink cartridges in digital printing, especially if not recycled properly, can contribute to electronic waste. Digital printers require energy for both printing and the equipment’s operation, impacting electricity consumption. While digital printing reduces paper waste through print-on-demand, substrate waste occurs when non-paper materials are used.

Best Practices for Choosing Between Offset and Digital Printing

- Minimize setup waste, calibrate accurately, and print only what is needed to reduce paper waste.

- Use eco-friendly inks made from sustainable materials, vegetable oils, or water-based solutions.

- Implement recycling programs for paper, plastics, inks, and other consumables to reduce landfill waste.

- Use energy-efficient lighting and equipment in the printing facility to reduce overall energy consumption.

- Educate employees about eco-friendly practices and the importance of sustainability, encouraging a culture of environmental responsibility.

By adopting these eco-friendly options and best practices, both offset and digital printing technologies can significantly reduce their environmental impact and contribute to a more sustainable printing and packaging industry. Businesses can make informed choices based on these practices to minimize their ecological footprint while meeting their printing needs.

Digital Printig and Offset Printing:Innovation and Trends

- Continuous improvements in inkjet technology lead to higher resolution, faster printing speeds, and a broader range of compatible materials in digital printing.

- While primarily used for prototypes and specialized applications, 3D printing is evolving. As it becomes more accessible and cost-effective, it might impact traditional printing for certain products.

- Continued development of sustainable printing options like water-based inks and biodegradable materials will drive eco-friendliness in offset and digital printing.

- Future printers will be designed for energy efficiency, reducing carbon footprint.

- Growing demand for personalized products, including packaging, marketing materials, and promotional items, will favor digital printing due to its ability to efficiently handle variable data printing.

- Advances in digital technology will enable cost-effective mass customization, allowing businesses to offer unique products at scale driving digital printing adoption for various applications.

- The rise of e-commerce and demand for quick delivery will continue to fuel the need for on-demand printing. Digital printing’s ability to produce small quantities efficiently positions it favorably in this trend.

- Printed materials might incorporate AR elements, enhancing interactivity and user engagement. Both printing technologies can complement AR applications, enabling immersive experiences.

- Embossing, debossing, foiling, and other specialty finishes will continue to be popular. These techniques can be applied to both digital and offset prints, adding value and differentiation to products.

- Hybrid printing solutions that integrate digital and offset processes will become more prevalent. Print service providers might combine the efficiency of digital printing for short runs with the cost-effectiveness of offset printing for bulk production, offering versatile and competitive services.

In the future, both digital and offset printing methods will coexist and evolve to meet the demands of various industries. Print businesses that strategically invest in these technologies, adapt to emerging trends, and offer a blend of traditional quality and innovative solutions will remain competitive in the dynamic printing landscape.

Final Thoughts

Now you understand what is offset printing vs digital printing. Offset printing, with the assistance of offset printing software, offers high-quality output, cost-effectiveness for large volumes, precise color matching, and versatility in paper types. It’s ideal for long print runs, consistent branding, and premium products. However, it involves longer setup times and higher initial costs.

Digital printing provides quick turnaround times, cost-effectiveness for short print runs, variable data printing capabilities, reduced waste through print-on-demand, and flexibility in customization. It suits low-volume jobs, personalized marketing materials, and projects with tight deadlines. However, there might be challenges with precise color matching, especially for specific Pantone colors.

“Choosing between offset and digital printing isn’t always simple; it really comes down to what you’re printing, how fast you need it, and the kind of results you want. Offset gives you that perfect consistency for bulk jobs, while digital makes short runs and custom orders quick and effortless.

At DesignNBuy, we get that most print businesses don’t rely on just one method. You’re balancing both, and we’re here to make that easier. Our web to print storefront bring everything together; managing offset and digital jobs from one place, cutting the manual work, and helping you deliver faster.

No matter how you print, we help you keep things running smoothly and your customers happy.

FAQs

What sets digital printing apart from offset printing?

Digital printing is a process of printing digital files onto various materials without traditional printing plates. Whereas, offset printing involves transferring an inked image from a plate to a rubber blanket onto the printing surface.

Which type of printing produces better quality?

The quality of both digital and offset printing can be excellent. However, the choice depends on the specific project requirements. Generally, offset and digital printing provides higher image quality, especially for high-volume projects, due to its ability to produce precise color matching and consistency.

Which printing is more environmentally friendly?

Digital printing is often considered more eco-friendly because it generates less waste and allows on-demand printing, reducing the need for large print runs. Offset printing requires the creation of printing plates, chemicals, and excess paper waste in the setup process.

Is digital printing cheaper than offset printing?

Digital printing can be more cost-effective for small to medium-sized print runs because it doesn’t require the setup costs associated with offset printing plates. However, for very large print runs, offset printing becomes more economical due to its lower per-unit cost.

Why would something be printed on an offset printer vs a digital printer?

Large print runs, precise color matching (such as Pantone colors), special finishes (like varnishes or embossing), and projects where high image quality and consistency are crucial; offset printing is advised. For short print runs, variable data printing (where each piece can be customized), quick turnaround times, and projects that require cost-effectiveness for small quantities, digital printing will be the best option.

Which advantage does digital printing offer over offset printing?

Digital printing allows for quick turnaround times as there’s no need for extensive setup. Files can be printed almost immediately, making it ideal for projects with deadlines and last-minute changes.

*This post has been updated on Oct 2025.