If you work in packaging, you understand that even if a design looks flawless on screen, it may not be successful in reality.

The fault is usually not with the artwork.

It is the dieline.

Dieline packaging is a technical blueprint that directs machines where to cut, fold, and assemble a box. Small mistakes can lead to costly rework, material waste, and missed delivery deadlines.

The scale is different in 2026. Packaging runs are faster, more personalized, and quite intolerant of faults, making proper dieline design essential.

In this article, we will go over what dieline packaging is, the various types utilized across packaging formats, and how to properly design dielines to avoid production troubles and delays.

Let’s start with the basics.

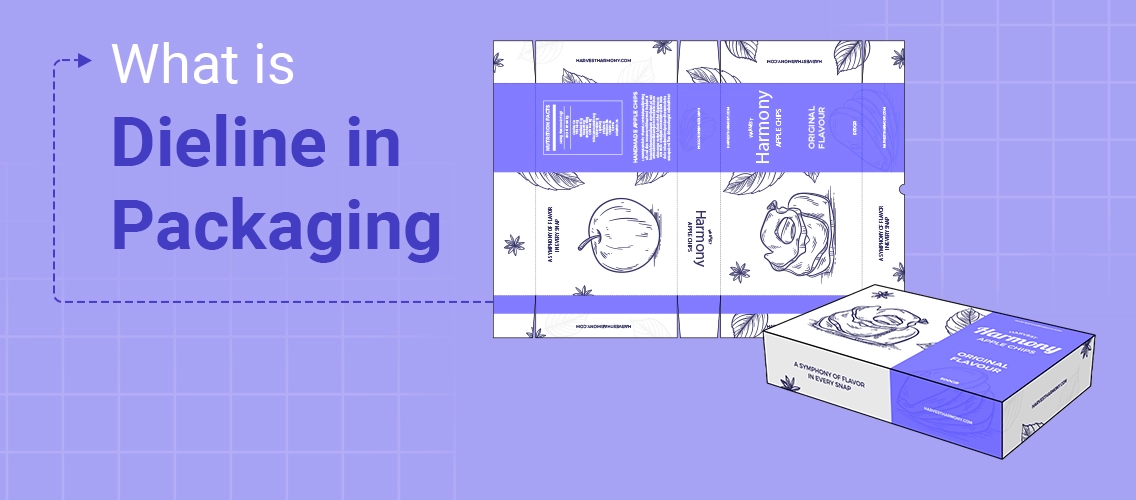

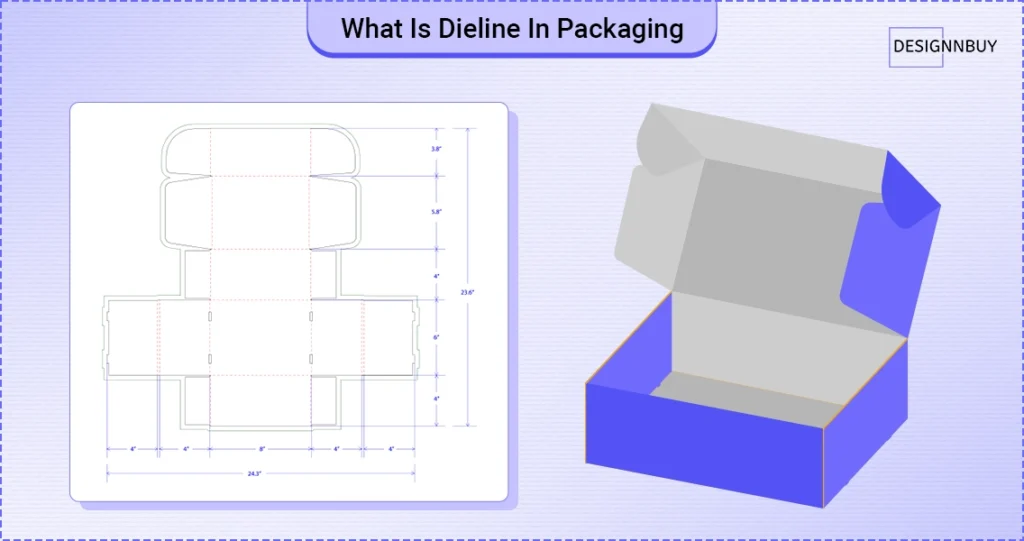

What Is Dieline in Packaging?

A dieline in packaging is a flat drawing that has been opened and laid flat on a table showing the exact shape of a package before it is formed into a box.

This drawing helps everyone involved understand how the package will finally look and function. Designers use it to place artwork correctly. Printers use it to check spacing and alignment. Production teams use it to ensure the package can be formed without issues.

A dieline includes visual guides such as outlines, panels, and edges that define where each part of the package exists. These guides help determine where text, images, barcodes, and logos should be placed so they appear correctly on the final box.

Without a dieline, even the best-designed packaging can fail during manufacture if it is not carefully prepped.

Why Dielines Matter in Modern Packaging Workflows

Dielines are essential throughout the whole packaging production process, not just during the design stage. When applied properly, they support teams in preserving control, precision, and consistency from the initial file to the end product.

1. Design & Prepress

Dielines serve as the structural basis for the placement of artwork during the design and prepress stages. In prepress, the same dieline becomes the reference point for checking bleed settings, safety margins, panel alignment, and overall print readiness. This is where preflight software plays a critical role—automatically validating artwork against the dieline to detect misalignment, missing bleed, or structural conflicts before files move into production.

2. Die-Cutting and Finishing

Die-cutting tools and finishing procedures are guided by dielines during production. To guarantee that packages are constructed correctly, machine operators rely on the cut paths, folds, and glue zones specified in the dieline. At this point, any error could result in material waste, weak frameworks, or miscuts.

Related Insight

Sticker production depends heavily on accurate dielines. Understanding the difference between kiss-cut and die-cut stickers helps packaging teams choose the right cut strategy, avoid material waste, and ensure clean finishing in high-volume print runs.

3. Client approvals and proofreading

Clients and internal teams can use dielines to see how the finished product will appear after it is put together. This clarity prevents last-minute adjustments that frequently cause production schedule disruptions and cuts down on approval delays, especially when the same dieline can be shared through design links, with “can view” and “can edit” (either of the accesses) keeping everyone aligned on a single version, and slowing the approval workflows.

4. Quality Control and Repeat Jobs

Dielines also facilitate long-term consistency and quality assurance. Approved dielines facilitate the management of recurring orders and provide a reference standard for inspection. Packaging teams save setup time and printing errors while ensuring consistent results across numerous print cycles by reusing validated dielines.

In practical terms, dielines maintain scalability, efficiency, and predictability in package production.

Quick takeaway: As soon as you think your packaging workflow needs to become faster and more automated, use dieline generators to control errors, costs, and turnaround times.

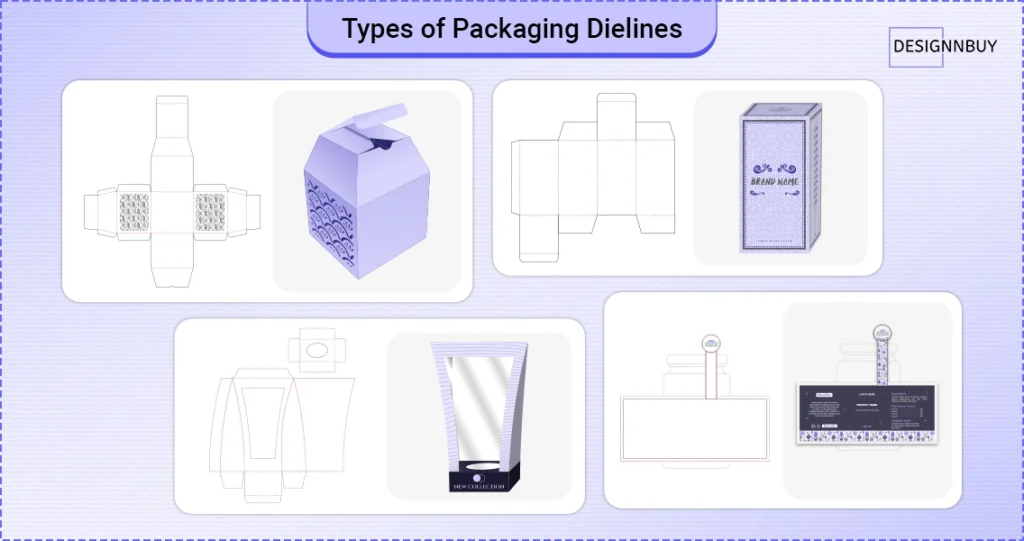

Common Types of Packaging Dielines

Packaging dielines differ depending on construction, material, and end use. Each type has a distinct production function, and utilising the correct dieline is crucial to avoiding setup problems, material waste, and finishing errors.

The following are the most frequently used packaging dielines in packaging and print workflows.

1. Box Packaging Dielines

Box dielines are the most commonly used in packaging production. They specify the structure of cartons and boxes, such as cut lines, fold areas, glue flaps, and lock mechanisms.

Here are some common examples:

- Folding boxes for retail items

- Rigid boxes for premium packing

- Corrugated boxes for transportation and protection

Accurate box dielines provide proper construction, strength, and visual alignment once the package has been folded and glued.

2. Label and Sticker Dielines

Label dielines specify the exact form and cut path for labels and stickers. These are especially useful for die-cut and custom-shaped labels.

Key considerations include:

- Layouts: sheet-based or roll-based

- Precise carved paths to prevent peeling and ripping

- Suitable distance between labels for completing

Cutting problems or misalignment during application might result from even minor dieline errors.

3. Flexible Packaging Dielines

Products like pouches, sachets, and wraps are packaged according to flexible guidelines. Because the material expands, bends, and seals during production, they demand additional precision.

Usually, they take into account:

- Tear notches and seal regions

- Folds and gussets

- Variable sizing according to the volume of the product

This is where things get complicated: precise dielines are crucial for both operation and shelf appeal since flexible packaging gives little room for error.

Common Dieline Packaging Mistakes – How to Avoid Them

Even seasoned teams encounter dieline problems, particularly when files are handled manually or recycled without checking.

Common Mistakes:

- Creating art without sticking to the dieline framework

- Ignoring safety zones and bleed results in text or visuals being cropped.

- Using out-of-date or inaccurate dieline versions among teams

- Failing to compare dielines with actual production materials

How to avoid them:

- Use standardised, production-approved dielines

- Lock artwork to the dieline structure

- Account for material thickness early

- Maintain version control

- Validate before production

Quick Takeaway: Dieline-related errors are a recurring packaging challenge across the industry. Even small inaccuracies in structure, dimensions, or alignment can create downstream issues that affect packaging consistency and print readiness.

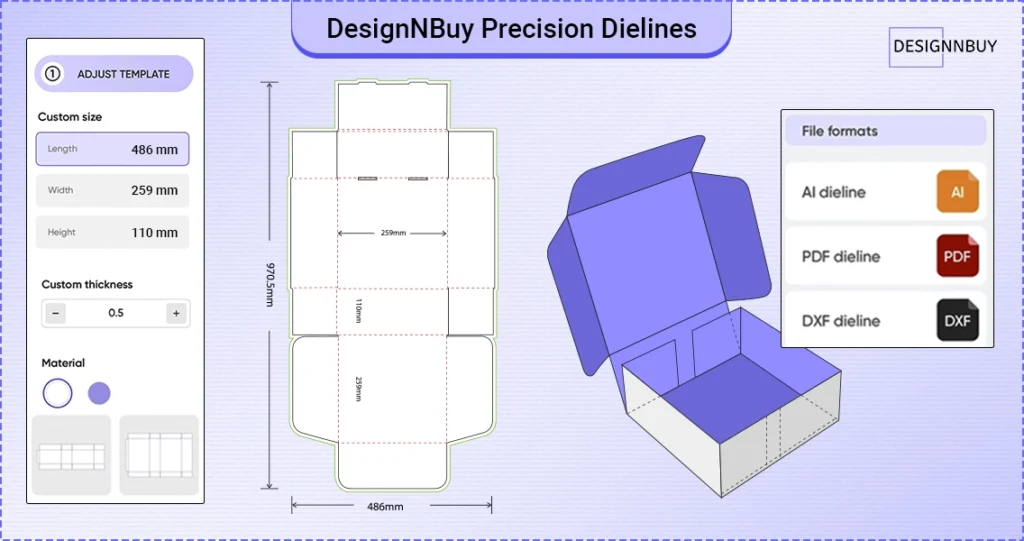

How DesignO Can Help Create Accurate Dielines in Packaging

Making a dieline is just one aspect of the process; once the package is put together, determining if it truly functions is the true challenge. This is where the use of DesignO web to print tool from DesignNBuy becomes a helping hand in the packaging process.

Print and packaging teams can specify precise dieline measurements from within the workflow rather than depending just on flat dieline files. These measurements serve as structural boundaries, ensuring that panels, folds, and artwork are positioned correctly from the beginning.

The 3D product configurator is one major benefit. Before the package is put into production, it enables teams to see how it will appear when folded and assembled. This makes it simpler to identify problems like:

- Artwork that extends past fold lines

- Panels or flaps that are not aligned

- Design components that are not part of the package structure

Teams may fix problems early rather than finding them during die-cutting or finishing by visually evaluating the design in 3D, and ultimately reducing artwork revisions.

Additionally, packaging teams can easily download production-ready dieline files, guaranteeing consistency between manufacturing and design approval. This lowers rework, cuts down on human corrections, and aids in maintaining accuracy throughout repeated tasks.

1. Predefined & Ready-to-Use Dielines

DesignO provides preconfigured dielines for common packaging types such as:

- Boxes

- Cartons

- Folding packages

These dielines already include cut lines, fold lines, and bleed areas, reducing setup time. Apart from this, you can even upload your own dielines into your web to print storefront in AI, PDF, or DXF file formats.

2. Accurate Cut, Fold & Safe Areas

- Cut lines: Indicate where the package will be cut.

- Fold lines: Show where the package will be folded.

- Safe zones: Ensure important content (text, logos) stays within printable areas.

This helps avoid production errors and reprints.

3. Multi-Side Support

Packaging dielines support multiple sides such as:

- Front

- Back

- Left

- Right

- Top

- Bottom

Each panel can be designed independently inside the DesignO editor.

4. Live Design Editor with Dieline Overlay

Customers see the dieline overlay directly in the design tool.

They can even place artwork while clearly seeing folds and cuts. This ensures designs align correctly after assembly.

5. 3D Preview with Dielines

Packaging products support real-time 3D preview. Customers can:

- Rotate the box

- See how artwork wraps across panels

- Validate placement before checkout

This dramatically reduces design mistakes.

6. Support for Standard & Advanced Packaging Models

You can choose from:

- Standard box models (basic packaging)

- Advanced/Exclusive models (complex shapes and structures)

Dielines automatically adapt to the selected model.

7. Print-Ready Output

Final output files include:

- Proper dieline layers

- Bleed and trim marks

- High-resolution print-ready files

This ensures smooth handoff to production or print partners.

If you want to know how DesignNBuy can facilitate the validation, reuse, and scaling of dielines by bridging the gap between dieline design and actual packaging production.

Getting Dieline Packaging Right in 2026

Accurate dieline packaging is now necessary in 2026 to prevent blunders, minimise rework, and maintain constant production quality. Businesses that depend on precise, organised timelines are better positioned to grow without experiencing operational friction as packaging gets more personalised and time-sensitive.

Workflows that treat dielines as reusable, validated assets rather than one-time files are being adopted by contemporary print and packaging teams. This change increases long-term efficiency, speed, and accuracy.

Frequently Asked Questions

A dieline is a technical blueprint that shows where packaging is cut, folded, creased, and assembled during production.

Printers or packaging engineers typically create dielines, while designers use them to position artwork accurately within structural constraints.

Yes. Approved dielines can be reused for repeat jobs or similar packaging formats, helping maintain consistency and reduce setup time.

With DesignNBuy’s web to print tool you can easily upload dieline formats such as AI, PDF, or even DXF. These formats are highly preferred because they preserve scale, accuracy, and editability throughout production workflows.

Dielines define exact cut, fold, and safety areas, helping teams catch structural issues early and avoid misprints, miscuts, and rework.