If you think all the boxes that you see in online deliveries are cardboard then guess what? They do look like cardboard but are actually called Corrugated boxes and their production is skyrocketing with the rise in eCommerce business.

So, what makes corrugated boxes different? What does it have to do with printers? Confused? Well, the corrugated box printing industry is a competitive one, but it is also lucrative. So whether you’re a startup or an experienced printer looking for a business opportunity or diversifying your offerings in the printing industry, this guide is for you.

Table of Contents

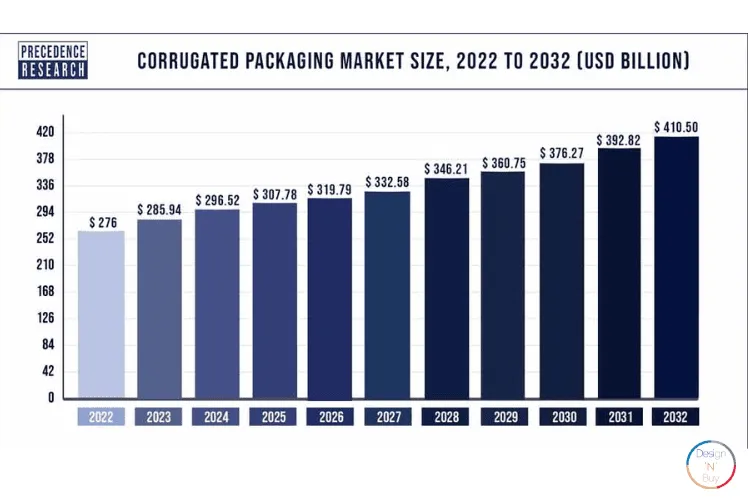

Corrugated Packaging Industry Market Status

The corrugated packaging industry is booming along with the expansion of the e-commerce and retail sectors. The global corrugated packaging market which was valued at $134.5 billion in 2021, is today growing at a compound annual growth rate (CAGR) of 4.1% such that by 2031, an estimated value of $198.8 billion will be achieved.

In fact, corrugated packaging has touched every industry sector be it food and beverage packaging, electronics, etc., and is ruling both online and offline worlds.Steps to Start an Online Corrugated Packaging Box Printing Business

Like any other online business, to get started with a corrugated box packaging business, you require a few basic setups along with some corrugated box-related essentials. So here’s how you can begin:

Study your target market to understand the demand for corrugated packaging boxes. Analyze your competitors to identify unique selling points and pricing strategies.

Develop a detailed business plan outlining your business goals, target audience, revenue model, and marketing strategies.

Register your business. Acquire necessary licenses and permits. Establish a legal structure for your business, such as a sole proprietorship or partnership, an LLC, or another form of organization.

Establish relationships with corrugated box manufacturers or suppliers. Verify that they can meet your quality and quantity standards.

Get a professional website designed on e-commerce platforms like Magento, Shopify, WooCommerce, or BigCommerce for a seamless online shopping experience, that features attractive images, descriptions, prices, and a simple checkout process.

Set up a secure online payment gateway for transactions.

Partner with reliable shipping carriers to ensure timely and safe delivery of your products. Determine shipping costs and policies, including international shipping if applicable.

Implement a robust quality control process to ensure that the packaging boxes meet the required standards. Inspect products before shipping to maintain customer satisfaction.

Focus on your branding and marketing. Build a strong brand identity. Promote your business using digital platforms.

Build trust and encourage repeat business by providing excellent customer service. Implement a system for handling customer inquiries, feedback, and returns efficiently.

Monitor your sales and customer feedback to identify areas for improvement. Consider expanding your product range or offering customization options to attract more customers.

Ensure compliance with environmental regulations and promote sustainable packaging practices if possible, which can be a strong selling point for environmentally conscious customers.

Stay updated with industry trends and technology to enhance your products and services continually. Gather feedback from customers and use it to make necessary improvements.

Starting an online corrugated packaging box business is no joke. Every step is crucial and requires extreme planning, dedication, and attention to quality and customer satisfaction if you want to build a successful online business in this niche.

Packaging Printing Companies Grew Faster with Web to Print Platform

Discover how six packaging printing companies achieved rapid growth by leveraging DesignNBuy’s powerful web to print platform.

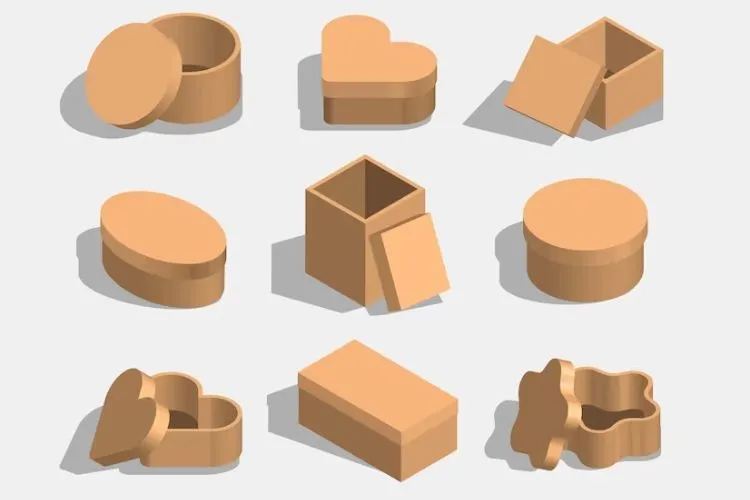

Offer a Range of Corrugated Box Types for Your Web to Print Store

When setting up an web to print store, offering a variety of corrugated boxes and packaging styles can cater to diverse customer needs. Here are some common types of corrugated boxes and different packaging styles that you can consider offering:

Custom Printed Boxes Varieties

1. Regular Slotted Container (RSC)

- Standard box with flaps that meet in the center when folded.

- Adaptable for a wide range of applications.

2. Half Slotted Container (HSC)

- Similar to RSC but with only one set of flaps.

- Ideal for products that need to be slid into the box rather than lifted.

3. Full Overlap Container (FOL)

- Flaps completely overlap, providing extra strength and protection.

- Suitable for heavy or fragile items.

4. Corrugated Trays

- Open containers without a lid, often used for display or organizing products.

- Useful for gift sets or promotional items.

5. Die-Cut Boxes

- Custom-shaped boxes made by cutting corrugated boards into specific shapes.

- Perfect for uniquely shaped products or promotional packaging.

6. Folding Cartons

- Lightweight, flat boxes that fold into a carton shape.

- Great for small items, cosmetics, or retail products.

7. Telescopic Boxes

- Consists of two separate pieces, a lid, and a bottom, that fit over each other.

- Provide excellent protection and are suitable for delicate items.

8. Gaylord Boxes

- Large, pallet-sized containers used for bulk shipments.

- Commonly used in industries like agriculture and automotive for bulk packaging.

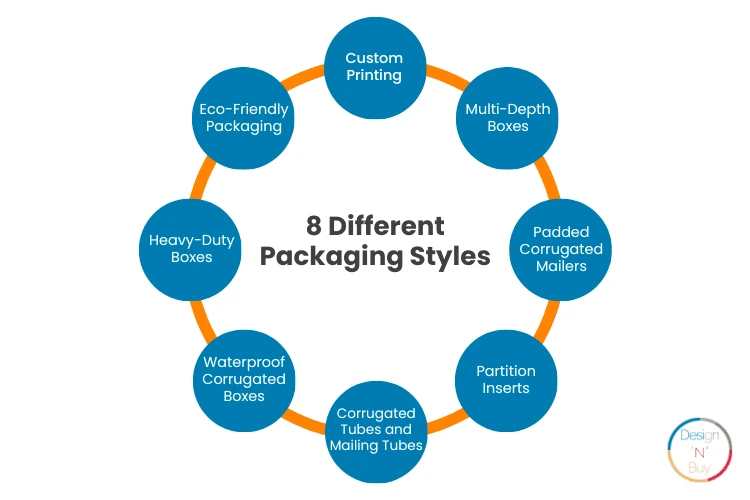

Different Corrugated Packaging Styles

1. Custom Printing

Offer custom printed boxes with your store’s branding, logo, and product information for a professional look.

2. Multi-Depth Boxes

Boxes with pre-scored lines that allow customers to adjust the height according to their needs.

3. Padded Corrugated Mailers

Corrugated mailers with built-in padding for added protection, suitable for fragile items.

4. Partition Inserts

Custom inserts inside the box to organize and protect multiple items within one package.

5. Corrugated Tubes and Mailing Tubes

Cylindrical boxes used for shipping documents, posters, or delicate items.

6. Waterproof Corrugated Boxes

Boxes treated with a waterproof coating or made from water-resistant material for shipping in damp conditions.

7. Heavy-Duty Boxes

Reinforced boxes designed for extra durability, suitable for heavy items or items that need extra protection during transit.

8. Eco-Friendly Packaging

Offer corrugated boxes made from recycled materials and promote eco-friendly packaging options to environmentally conscious customers.

By providing a variety of these custom corrugated boxes and packaging styles, you can cater to different customer requirements, ensuring that their items are securely and professionally packaged when they arrive.

Top-Selling FEFCO Box Styles in 2024

What are FEFCO codes and why are they important. Here are some of the most popular

FEFCO box styles that online businesses are leveraging.

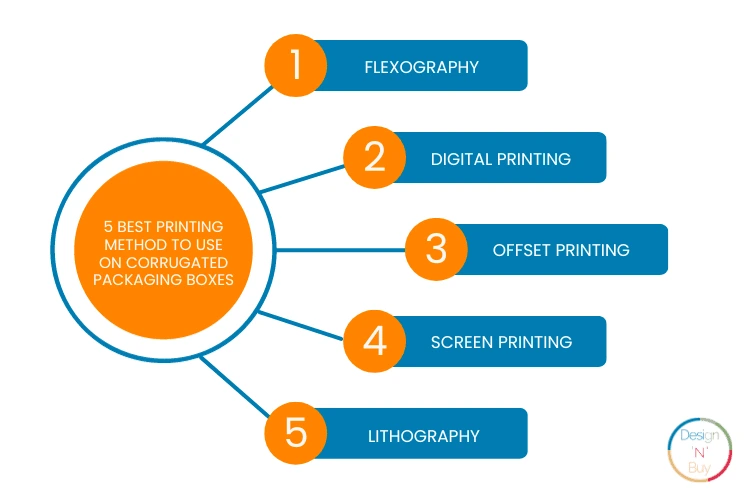

The Best Printing Method To Use On Corrugated Packaging Boxes

The choice of printing method for corrugated packaging boxes depends on various factors, including the design complexity, budget, order quantity, and desired printing quality for custom boxes.

Here are some common types of corrugated box printing methods used for large orders of corrugated packaging boxes, each with its advantages:

1. Flexography Printing Method for Corrugated Boxes

One of the most common printing methods being used for corrugated boxes Flexographic printing is a versatile and cost-effective option for large-volume box printing. Flexography can handle various types of inks and is suitable for simple to moderately complex designs. It’s ideal for high-volume production runs and offers relatively fast printing speeds.

2. Digital Printing Method for Corrugated Boxes

Offers high-quality printing with the advantage of customization. It’s suitable for short to medium runs and allows for variable data printing, making it perfect for personalized packaging. Digital printing doesn’t require printing plates, which makes it a more economical option for smaller quantities and quick turnaround times. You can check out the digital printing software for a more detailed overview of the features.

3. Offset Printing Method for Corrugated Boxes

Provides high-quality and sharp images. It’s best suited for high-volume printing on corrugated boxes with intricate designs. Offset printing offers consistent and accurate color reproduction, making it a good choice for printing on corrugated boxes with detailed graphics or photographs. However, it’s usually more expensive than flexographic printing for printing on corrugated boxes. You can check out the offset printing software for a more detailed overview of the features.

4. Screen Printing Method for Corrugated Boxes

A versatile option for printing on various surfaces, including corrugated boxes. It’s suitable for simple designs with bold colors. Screen printing can create a tactile texture on the surface of the box, adding a unique feel to the packaging. However, it’s not as cost-effective for large production runs compared to flexography. You can check out the screen printing software for a more detailed overview of the features.

5. Lithography Printing Method on Corrugated Boxes

Also known as litho-lamination, involves printing onto a paper or film substrate, which is then laminated onto a corrugated board. This method provides high-quality printing with fine details and is suitable for high-end packaging applications. It is expensive and time-consuming but offers excellent print quality.

Choosing the Best Method

For short runs and customization digital printing is often the best choice.

For medium to large quantities and high-quality printing, offset printing is a popular option.

For large quantities and cost-effectiveness, opt for flexography.

While where vibrant colors and unique textures are desired, screen printing is an ideal option.

Consider your specific requirements, budget constraints, and the visual appeal you want for your corrugated packaging boxes when choosing the printing method. It’s also advisable to consult with printing professionals or companies experienced in doing corrugated packaging box printing to determine the best printing solution for your needs.

How AI & Web to Print are Transforming Wine, Perfume & Cosmetic Packaging

Explore how AI and web-to-print technologies are revolutionizing label design for

wine, perfume, and cosmetic packaging.

Machines and Materials Required for Corrugated Box Packaging Business

Starting a corrugated box packaging business requires various machines and materials to produce high-quality packaging products efficiently. Here are the essential machines and materials you’ll need for a corrugated box packaging business:

Machines Requires for Corrugated Box Printing:

Corrugating Machine (single/double facer)

To create a corrugated board by gluing the liner paper to the corrugated medium paper.

Slitter Scorer

Machine for slitting and scoring corrugated sheets to the required dimensions.

Printer Slotter Die-Cutter

Printing unit for adding designs, slotting unit for cutting slots, and die-cutting unit for shaping boxes.

Folder Gluer Machine

Equipment for folding, gluing, and forming corrugated sheets into boxes.

Stitching Machine

Used for stitching boxes for additional reinforcement.

Strapping Machine

Equipment for bundling and securing finished boxes.

Die-Cutting Machine (Flatbed or Rotary)

Flatbed or Rotary die-cutting machines for cutting out box shapes from corrugated sheets.

Laminating Machine

For laminating corrugated sheets with other materials for added strength and appearance.

Waste Paper Baler

For compacting waste corrugated material into bales for recycling or disposal.

Quality Control Equipment

Moisture meters, thickness gauges, and other instruments for ensuring product quality.

Design Software

Computer-aided box design software for creating box designs and layouts.

Air Compressor

Provides compressed air for pneumatic operations in various machines.

Safety Equipment

Emergency stop buttons, guards, safety sensors, and personal protective equipment (PPE) for operators’ safety

Office Equipment

Computers, printers, phones, and other office supplies for administrative tasks and customer communication.

Transportation Vehicles

Trucks or vans for transporting raw materials, finished products, and equipment.

10 Reasons You Need Online 3D Packaging Design Software

Discover why packaging printing companies should adopt online 3D packaging design software. Enhance visualization, engage customers, and improve design efficiency effortlessly.

Materials Requires for Corrugated Box Printing:

Corrugated Paperboard

Different flute profiles (A, B, C, E, etc.) and grades (single wall, double wall, triple wall) for various box strengths and purposes.

Linerboard

Paperboard, used as the outer layer of corrugated board that provides a smooth surface for printing and enhances the box’s appearance.

Adhesives

Starch-based or synthetic adhesives used to bond corrugated layers together during the manufacturing process.

Printing Inks

Water-based or solvent-based inks for printing designs, labels, and information on the boxes.

Pallets and Skids

Wooden or plastic platforms for stacking and transporting finished boxes.

Strapping Material

Polypropylene or steel straps, used for bundling and securing boxes for shipping.

Protective Packaging Materials

Bubble wrap, foam, or other cushioning materials for protecting fragile items inside boxes.

Recycled Paper

Used for producing eco-friendly and recycled cardboard boxes.

Machines and materials that align with the production volume, budget, and the types of corrugated boxes that one intends to produce matter the most in the corrugated box industry. Therefore they must be hand-picked carefully. Additionally, you can consider the availability of technical support, spare parts, and maintenance services when selecting your machinery and material suppliers. If needed, seek the help of other corrugated box industry’ experts or consultants to make informed decisions based on your specific business requirements.

Technology and Software Required For Corrugated Box Printing

Indeed, technology and software play a crucial role in the modern packaging industry, enabling businesses to streamline operations, enhance customer experience, and offer personalized custom corrugated box packaging and solutions.

Here are some essential technologies and software tools that can benefit your corrugated box packaging business:

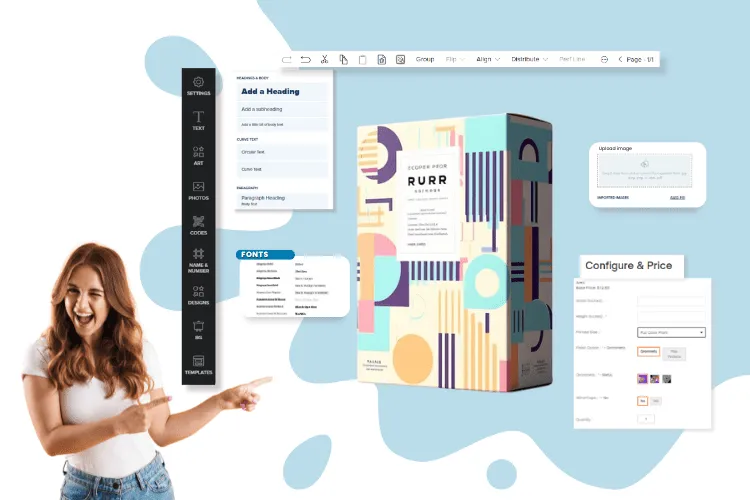

Online Box Designer In Your Web to Print

Implementing web-based packaging design software on your website will do all the job you need to sell corrugated boxes. It easily integrates with the website, enabling customers to customize and order packaging online. They often come with pre-made templates and customization options.

Additionally, you can use tools and software such as product configurators, web-to-print management software, automation software, print estimating, and job management software to improve your operational efficiency, increase customer satisfaction, and ultimately contribute to the success of your custom box packaging business.

Cosmetic Agencies can Boost Sales with Web To Print

Cosmetic manufacturers can offer their clients to create personalized label designs online for various beauty products such as lipstick, mascara, skin care, makeup accessories or perfume.

Benefits of Offering Custom Corrugated Boxes on Your Web to Print Platform

Offering custom printed corrugated boxes, on your web-to-print platform can provide several benefits to both your business and your customers. Here are some advantages of allowing customers to personalize their custom corrugated boxes using your online web to print platform:

Enhanced Customer Experience

- Customers can design boxes that suit their specific needs, creating a more engaging and personalized experience.

- A user-friendly design tool makes it easy for customers to customize their boxes, boosting satisfaction.

Increased Sales and Revenue

Customization options can increase conversion rates because customers like to personalize products to their liking.

Additionally, offering unique and high-quality options like material and finish selections can make a product stand out from the competition.

Operational Efficiency

Customization details can be seamlessly transferred to production systems, reducing the chances of errors and streamlining the manufacturing process.

Automated systems decrease the need for extensive back-and-forth communication, saving time and resources.

Competitive Advantage

Providing personalized packaging sets you apart from competitors offering standard solutions, attracting customers seeking unique and tailored options.

Customers are more likely to return to your platform if they have a positive and unique experience designing their packaging.

Cost-Efficiency

Automation and standardized customization processes can reduce operational costs in the long run.

Custom orders can be produced on demand, minimizing excess inventory and associated costs.

Market Research and Feedback

Analyzing customization trends and customer preferences can provide valuable insights into market demands, helping you adapt your offerings accordingly.

Direct interaction with customers during the customization process can lead to valuable feedback, enabling continuous improvement.

Sustainability and Waste Reduction

Offering eco-friendly materials and encouraging sustainable packaging practices aligns with the growing demand for environmentally conscious solutions.

On-demand production reduces the chances of overproduction and excess inventory, minimizing waste.

Brand Image and Trust

A well-executed web-to-print platform conveys professionalism and expertise, building trust with customers.

Allowing customization enhances your brand’s perception as innovative and customer-focused.

By offering custom-printed corrugated boxes, on your web-to-print platform, you not only cater to the evolving needs of your customers but also create a more efficient and competitive business model. Customization can foster customer loyalty, drive sales, and establish your brand as a leader in the packaging industry.

Box Design Software: Offer Customizable Patterns and Colors

Our online box design software lets customers choose patterns and colors as they design,

ensuring personalized and engaging products.

Start Corrugated Box Packaging Printing Now!

Already a lot of time has passed since you were wondering whether or not to invest in the corrugated box packaging printing business because the competition has become cut-throat and to survive you need to be unique, serve better, and act smarter. Using this guide you too can join the bandwagon and launch your custom corrugated box printing business in a way that you will get a sure shot at success.

FAQ

Most Frequently Asked Questions and Their Answers

Yes, due to the rise in online shopping, corrugated boxes are in high demand. So, it is the right time to invest in the corrugated box manufacturing business.

Printed Corrugated boxes are typically printed using flexographic, offset, or digital printing methods. The choice of printing method depends on the packaging box design software complexity, budget, and quantity of boxes to be produced. Flexographic printing methods is commonly used for large-scale orders due to its cost-effectiveness, while offset printing offers high-quality results suitable for intricate designs. Digital printing is ideal for short runs and customization.

Offset printing is often considered to offer the highest quality printing on corrugated paperboard boxes. It provides sharp and detailed images, making it suitable for printing intricate designs, gradients, and high-resolution graphics. However, the quality also depends on the expertise of the printing service and the materials used.

You can find customers easily via various mediums by attending industry events, trade shows, and conferences to network with potential clients and suppliers, creating a professional website to showcase your products and services, utilizing social media platforms to connect with a wide audience, approaching local businesses, especially those involved in e-commerce, manufacturing, or retail, as they often require customized packaging solutions, word of mouth publicity from your loyal customers, promotion, and marketing.

Since the future of the corrugated cardboard packaging business depends on market trends, economic factors, environmental concerns, and technological advancements it will keep changing. However, based on its current growth it can be said that this year too will end with a huge turnover for the corrugated packaging industry.

Do you have any more questions? Contact our experts

More For You:

- Custom Box Printing and Packaging In The US: An Overview, Benefits For Printers and Top Players…Read More

- Holiday Packaging Boxes: Tips for Packaging Printers on Selling Custom Packaging Boxes…Read More

- The Impact of Innovative Packaging Printing and Trends in Australia…Read More

- 19 Types of Packaging Boxes for Online Custom Packaging Businesses…Read More

*This post has been updated on July 2024.