Is your print shop still relying on emails, manual file checks, or calls to manage packaging orders?

You might offer great-quality custom packaging, but the order process is often chaotic and slow. And with nearly 73% of consumers saying packaging design influences their purchase decisions, that’s a problem you can’t ignore.

In fact, the custom packaging market is expected to grow to $37 billion by 2030, fueled by the rise of D2C brands and eCommerce subscriptions. But here’s the catch: most print providers still use outdated workflows that struggle to keep up.

And when your customers expect real-time previews, custom sizes, and fast delivery, a disjointed process can cost you conversions.

So, how do you make custom packaging orders easier for both your team and your clients?

In this blog, we’ll show you exactly how web to pack solutions help streamline your operations, eliminate errors, and create a better buying experience.

What Is a Web to Pack Solution?

If you’ve been running a packaging print business for a while, you know how complex custom orders can get. Sizes vary, materials change, die lines go missing, and there’s always one last-minute edit before going to print.

That’s exactly the kind of chaos a web to pack solution helps you avoid.

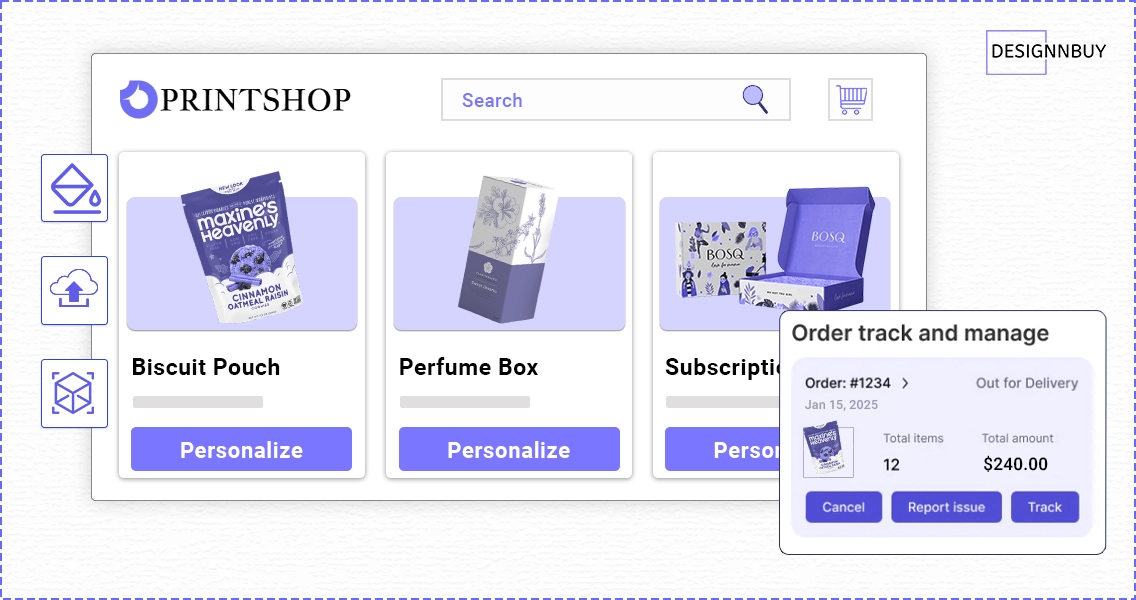

At its core, web to pack solution is built specifically for the needs of packaging businesses. It brings together an interactive online storefront and a packaging-specific design editor so your customers can configure, customize, and preview their packaging before placing an order.

Instead of emails and endless revisions, customers simply choose the box size, select materials and finishes, upload or design artwork online, and get an instant 2D or 3D preview of the final product. Dielines and specs are auto generated, saving time for everyone involved.

But it doesn’t stop at the front end.

Behind the scenes, the system pre-checks files for resolution, color accuracy, bleed, and die line alignment. Once approved, print-ready files are automatically routed to production, and everything from job tracking to customer status updates can be managed through a single dashboard.

In short, web-to-pack solutions give your customers more control and clarity, while helping your team work faster, smarter, and fewer errors.

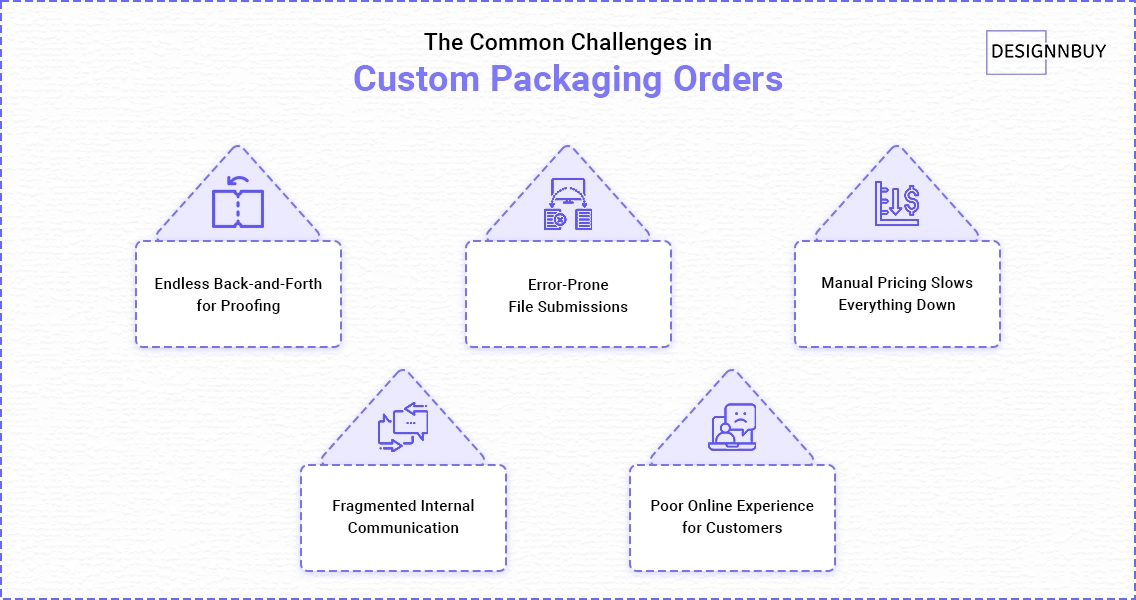

What Are the Common Challenges in Custom Packaging Orders?

Managing custom packaging orders can sound like a high-margin opportunity until you’re stuck chasing approvals, fixing files, or manually calculating quotes. If you’re a packaging print service provider (PSP), you know how fast things can spiral. Let’s break down the most common roadblocks that slow down operations and impact your bottom line.

1. Endless Back-and-Forth for Proofing

Manual proofing is still a norm for many PSPs. Need a die line approved? Fixing a color mismatch? That usually means 3–4 email exchanges per order. The result? Delayed production and missed delivery windows.

2. Error-Prone File Submissions

Customers often submit designs in the wrong formats RGB instead of CMYK, no bleed area, or low-resolution images. You end up spending time correcting files or, worse, reprinting them at your own expense.

3. Manual Pricing Slows Everything Down

Custom packaging rarely fits into a fixed pricing model. Every time a customer requests a change in size, finish, or quantity, your team must recalculate quotes manually, increasing response time and leaving room for human error.

4. Fragmented Internal Communication

Sales, design, and production teams often operate in silos. They use different tools, lack centralized order visibility, and rely on offline workflows that don’t sync.

5. Poor Online Experience for Customers

Many print shop websites still operate on a “submit your file” model with no live customization. Customers can’t visualize their packaging in real time and that leads to friction and cart abandonment.

Talk to our experts to discover how we can help you overcome every challenge and drive real results.

How Does Web to Pack Technology Simplify Custom Packaging Orders?

If managing custom packaging jobs still feels slow, manual, or error-prone, your packaging business needs an upgrade. Web to pack technology brings automation, accuracy, and customer self-service together in one seamless platform. Here’s how it simplifies your entire packaging order workflow:

Custom Packaging Configuration with Live Pricing

Let customers choose dimensions, box types, materials, finishes, closures, and more with instant parametric pricing based on all variables, no manual quoting required.

Real-Time 2D/3D Previews (with Interactive Lid Open/Close)

Buyers get accurate 3D previews from every angle even with the lid opened or closed, so they can visualize the final product before hitting “Buy.”

360° Personalization Across All Sides

Customers can design every surface: top, bottom, front, back, and side panels ensuring full creative control and on-brand packaging.

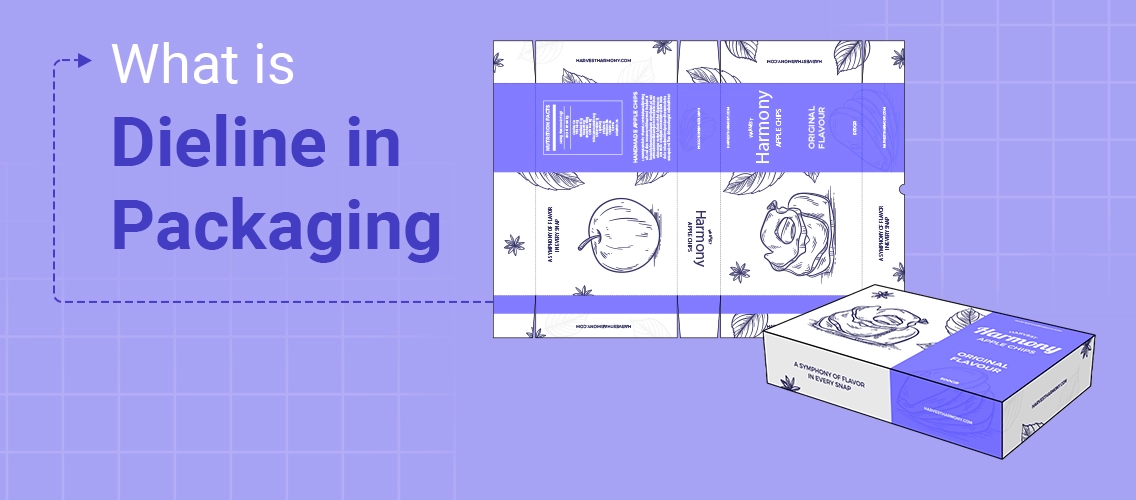

Instant Die line Generation

As customers define box dimensions and styles, die lines are automatically created perfectly aligned to specs, saving hours of back-and-forth.

Auto Preflight Checks

The preflight feature validates every file for print-readiness: checking bleed, resolution, color mode, die line placement, and more. It catches and corrects errors before they become reprints.

Production-Ready File Output

Approved designs are auto-converted into press-ready PDFs with specs embedded; no manual editing or reformatting needed.

Job Management & Routing to Production Systems

With job management and routing features, files are instantly sent to your RIP or finishing systems, keeping your production queue fast, accurate, and hands-free.

Dynamic Dashboards for Order & Workflow Management

From artwork approval to delivery, track every stage of the order in one dashboard with print workflow management feature. Your team stays aligned and your customers stay informed.

Customer-Friendly Reordering

Past orders are saved, editable, and re-orderable in just a few clicks, helping you build repeat business with less effort.

With web to pack solutions in place, you’re not just speeding up your workflow, you’re offering an experience today’s eCommerce brands expect: custom, visual, and on-demand.

Conclusion: Ready to Simplify Custom Packaging Orders?

Simplifying custom packaging orders isn’t just about adding automation; it’s about creating a better experience for both your customers and your team.

With web to pack technology, you can reduce errors, speed up production, and make it easier for buyers to design and order packaging on their own. From real-time 3D previews to automated die line generation, you’re building a system that works smarter, not harder.

Whether you’re a growing print shop or an established PSP, adapting to today’s packaging demands is key to staying competitive and ahead of everyone.

At DesignNBuy, we help print service providers like you offer smarter, faster, and more profitable custom packaging with a fully integrated storefront and web to pack design editor. Whether you’re selling corrugated boxes, folding cartons, or mailer packaging, our platform ensures every order is print-ready, error-free, and production-optimized.

See Web to Pack in Action

Book a personalized demo & discover how it can simplify your entire packaging order process.

FAQs

How is web to pack different from standard solutions?

Web to pack is tailored for packaging print providers. It supports product-specific needs like die line generation, 3D packaging previews, parametric pricing, and multi-surface design something standard platforms don’t offer.

Can I offer different box styles and sizes with Design’N’Buy’s web-to-pack solution?

Absolutely. Our web to pack solution allows you to offer folding cartons, rigid boxes, mailer boxes, and more with custom sizes, finishes, and design templates.

Will the system generate die lines automatically for each custom order?

Yes. Die lines are created instantly based on the dimensions and box style chosen by the customer, which reduces production errors and proofing delays.

Is it suitable for both B2B and D2C packaging providers?

Yes. Whether you’re serving businesses or end consumers, DesignNBuy’s web to pack solution offers the flexibility and customization your buyers expect.

What kind of support does DesignNBuy offer for onboarding?

Our team helps you with everything from storefront setup and product configuration to team training so you can start taking orders confidently from day one.

Looking for more? Check out our other blogs:

Why eCommerce Packaging Is the Next Big Opportunity for Modern Print Businesses

Why Custom Paper Bags Are a Must-Have for Print Service Providers

Top AI Models and Tools for Print Service Providers and Packaging Businesses

How to Start Selling Custom Pouches Online: A Complete Guide

- Major Challenges in Offering Custom Size and Personalized Packaging Products Online